How to Balance an Industrial Dust Collection Ventilation System

“What do You Mean by Balancing my Baghouse Dust Collector's

Ventilation System?”

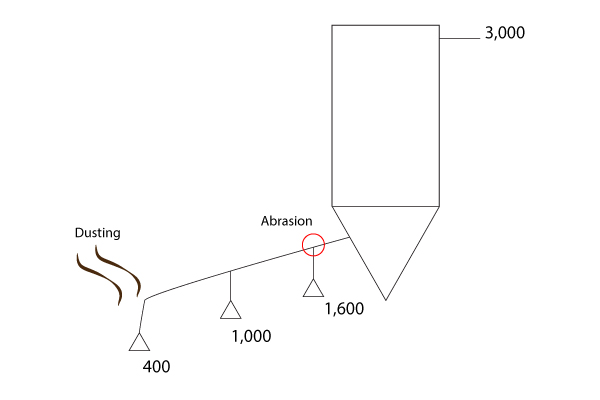

Let’s look at an example where this balancing issue may arise. Take a system that has a capacity of 3,000 CFM. Now let’s say this system is intended to suction 1,000 CFM from each vent point. In this particular scenario if a balancing procedure has not been performed then it’s likely that each vent point will produce different results; i.e. 1,600 CFM at one vent point and 400 CFM at another.

Unbalanced ventilation system example.

So why does this happen?

On a multiple-branch system with no slide gates or blast gates, each ductwork branch will present a different restriction to flow. The ones with longer or smaller diameter duct runs will present more restriction to flow than branches with larger diameter or shorter duct runs. The fan will pull from the points with least restriction, so some branches will suction more and others less than their intended share of flow.

Why you should be concerned.

Over time if the system continues to operate at an unbalanced rate issues will arise. Dusting and abrasion can occur an multiple vent points. The damage to your system will result in more down time in order to address the new problems that have been created.

The Solution!

In order to get the vent points to suction at the same rate, the flows need to be adjusted. Slide-gates or blast-gates can be used at the vent points with lower resistance to balance out the flow of the system as a whole.

The blast-gate field balancing procedure is as follows:

1. Move all blast gates to their full open position.

2. Determine the order of the branches, starting with the ventilation point closest to the fan.

3. Gradually close the blast gate until slight pressurization occurs. At this point, open gate slightly and secure.

4. Verify fan flow is near the intended flow volume and readjust fan damper, if necessary.

5. Repeat steps 3 and 4 with the next to closest branch, until all have been adjusted.

On systems with 8 or more vent points, or where a definite order of adjustments cannot be easily determined, pressure readings can be made at each duct/hood connection to confirm similar readings. This also helps in reducing trial-and-error in the above procedure.