Bottom Load VS Top Load Baghouse

Today we’re going to discuss the differences between a bottom load pulse-jet baghouse and a top load pulse-jet baghouse. In summary, you always want a top load pulse-jet baghouse.

But why is that?

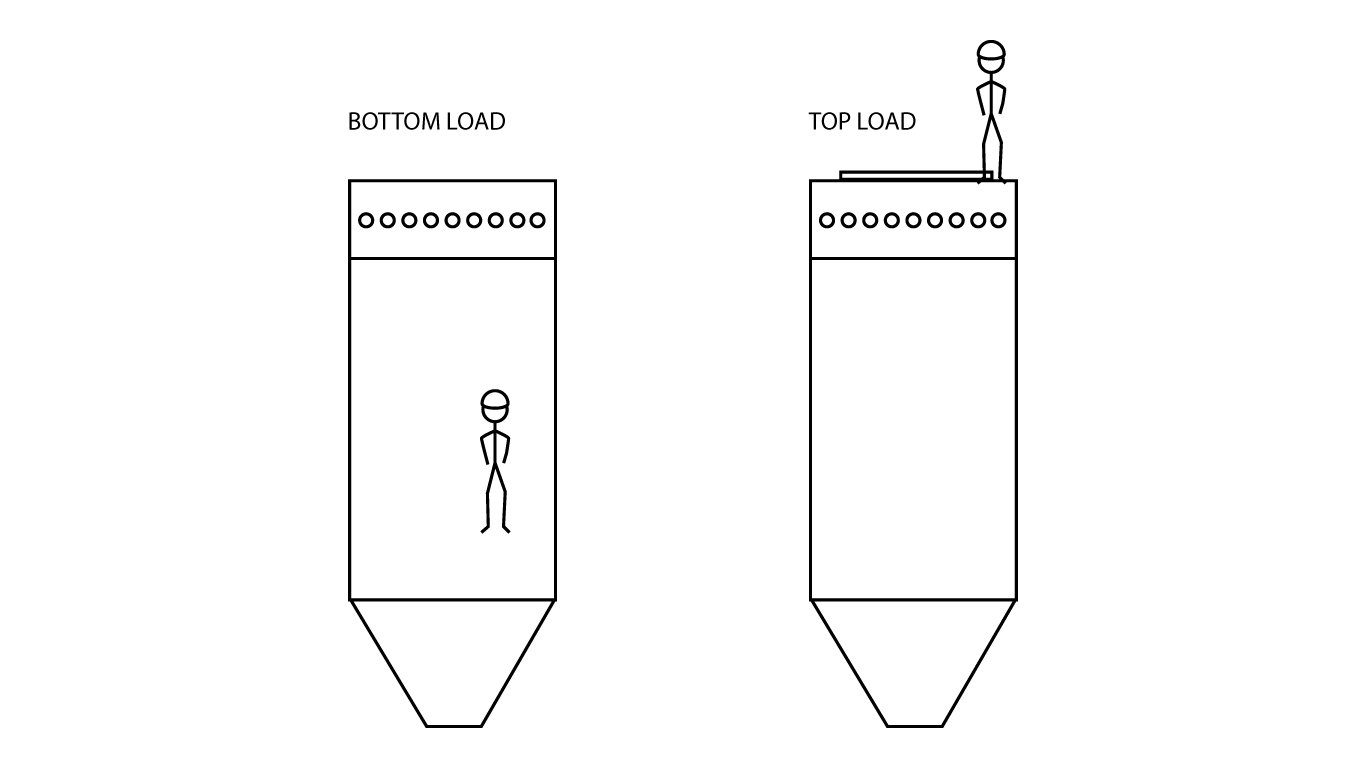

We will first look at top load baghouses. On a top load the maintenance worker is on the clean side of the baghouse, they can access the full array of bags and do a good job of installation. Top loads are safer, easier to change out bags and simply better.

On the bottom load baghouse the maintenance worker has to access the bags from the dirty side, which is far from pleasant. While it may not matter to most plant managers how pleasant the dirty side of their baghouse is, it can result in the worker doing a poor installation due to the environment. Having a poor filter bag change out can ultimately result in emissions out the stack.

Since top load baghouses appear to be the superior option, why would anyone install a bottom load baghouse? If there is a space restriction, such as a roof, this would warrant the need for a bottom load baghouse. The reason behind this is that the roof restricts the ability to pull a cage from the top of the unit.

If you’re sitting here thinking “I have a bottom load system that has no roof restriction” then you’re in luck! At IAC we can convert bottom load units into top load units by changing the top module and installing hand rails.

If you’d like to discuss converting your bottom load baghouse into a top load call us at 800-334-5511.