Pulsing Setpoints in a Baghouse Control System

Having incorrect setpoints on your control system of a baghouse can be a big source of problems for your system.

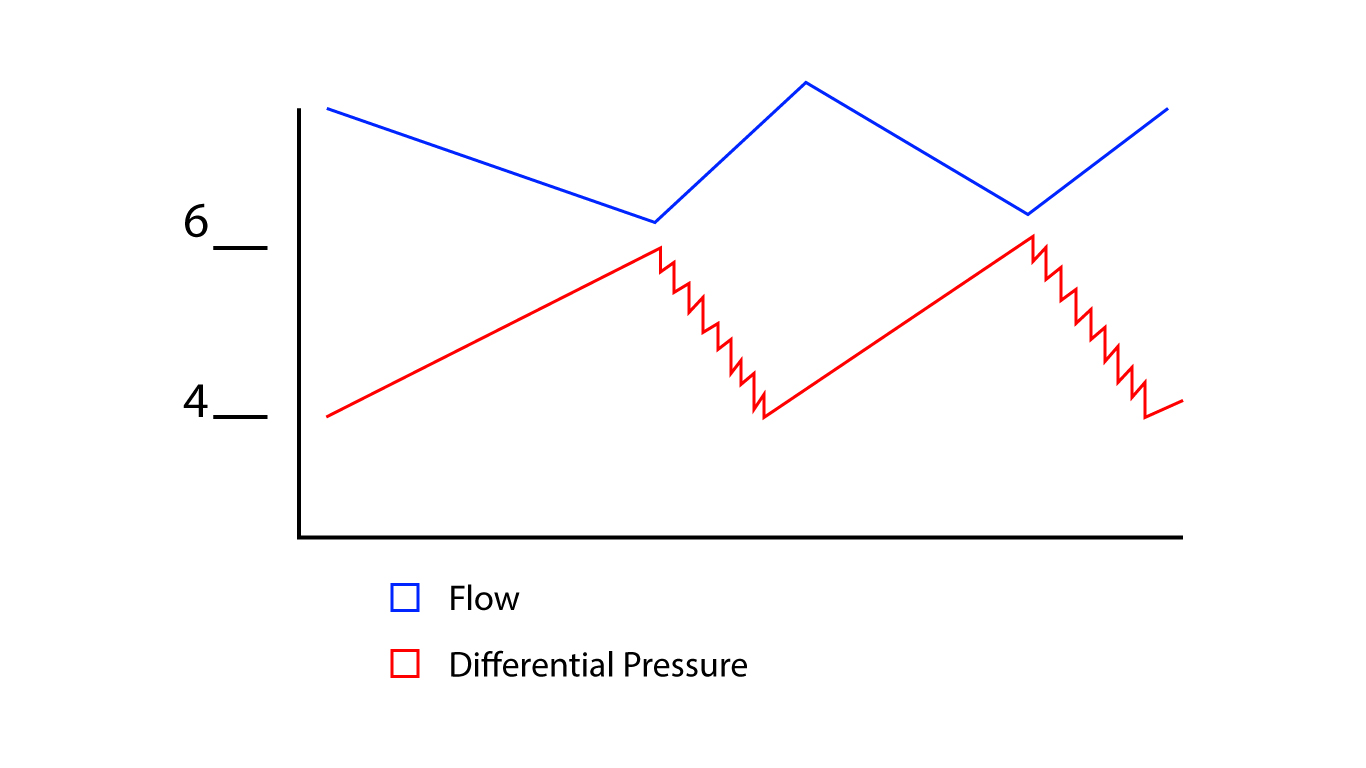

You’ve probably heard that a good differential pressure is between 4” and 6”. Because of this many people make the mistake of placing their setpoints in their control system to that range. This poses a problem as the differential pressure rises until it reaches 6 inches and then the system pulses continually until the pressure reaches 4 inches. The pattern of pulsing within the 4”-6” range causes fluctuation in differential pressure and in flow, both of which are an issue.

The flow within the system cannot remain consistent as it will being to mirror the up and down pattern of the differential pressure. Most importantly, the system discharges only upon pulse. With the continual pulsing from 6 inches to 4 inches, the hopper of the baghouse is bound to overload.

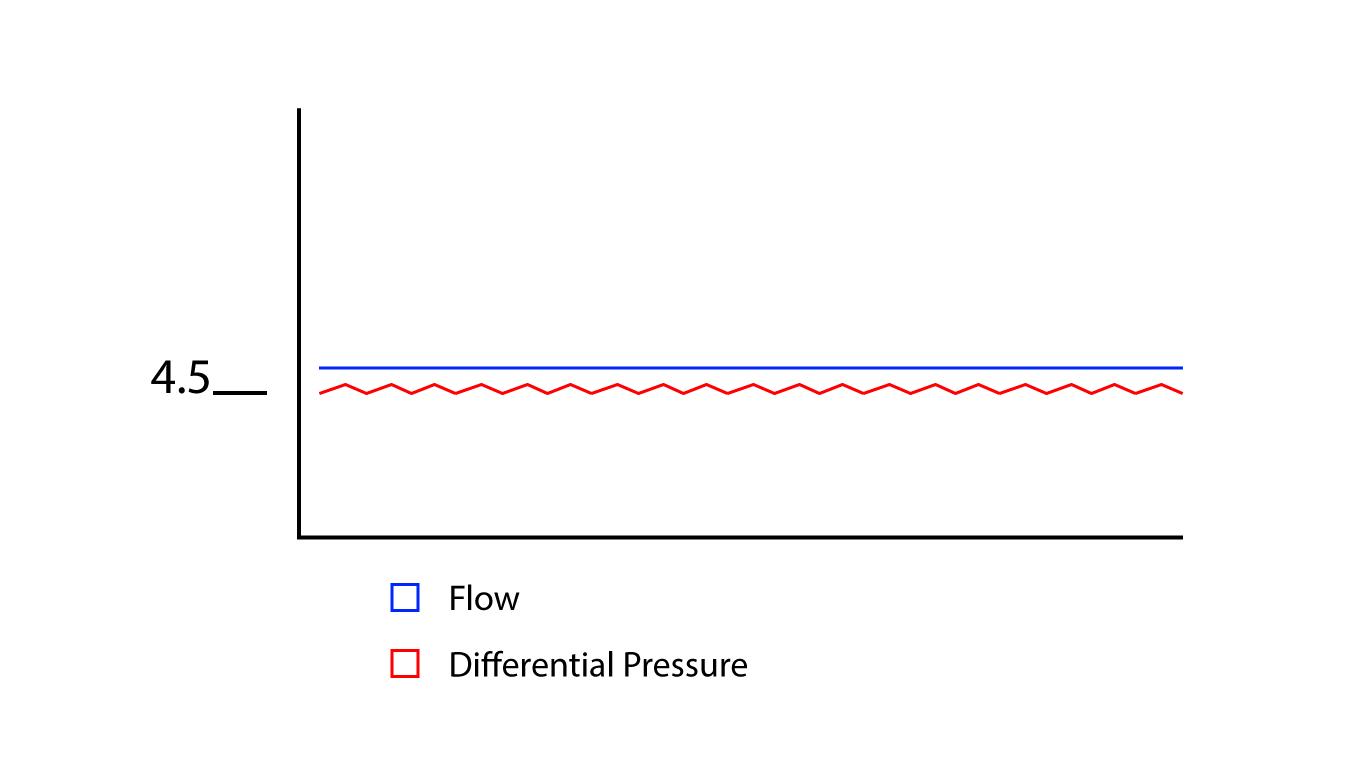

The key is to get rid of pulsing setpoints and use just one pulsing setpoint, let’s say 4 1/2’” as your control. Utilizing one setpoint will stabilize your differential pressure and flow and result in your discharge being sporadic, so that the hopper does not overload.

If you have any questions about this topic and how it relates to your system, contact us today!