SNCR NOx Control: Efficient Reduction Solutions for Cement Plants

The cement production industry is one of the world's leading contributors to greenhouse gas emissions, accounting for 8% of global CO2 emissions. Among the pollutants produced during the cement manufacturing process are Nitrogen Oxides (NOx), which cause smog, acid rain, and contribute to the formation of fine particulates. In addressing this challenge, Selective Non-Catalytic Reduction (SNCR) technology has emerged as a key solution to significantly reduce NOx emissions, thus promoting cleaner production in the cement industry.

SNCR is a post-combustion technology for controlling NOx emissions. The process involves injecting a reagent, typically ammonia or urea, into the combustion flue gas stream. The reagent reacts with the NOx in the flue gas to form harmless nitrogen and water vapor, reducing the emission of NOx into the atmosphere.

Producing cement is not an easy process. After extracting silica, limestone rocks, and calcium carbonate from the earth through mining processes, the limestone enters the cement factory and it is crushed in various stages. Next, it is separated according to the values of calcium carbonate based on the type of cement being created. From here, other artificial elements may be added and uniform destruction down to a powder, known as the raw meal, is created.

IAC specializes in cement industry pollution control technologies, plus ventilation systems, dust collection systems, and specialty construction crews for work such as installing roller press systems. A complete list of products and services can be found on our 24/7 Response Teams page.

Cement Kilns, notably through the Pre-Heating and Rotary Kiln process, maintain extreme levels of combustion. This rapid combustion creates the byproduct of Nitrous Oxide (NO) and Nitrous Dioxide (NO2), which are generally termed together as NOx.

Effective SNCR NOx Control for Reducing Emissions in Cement Production

NOx emissions are a central topic in modern air pollution conversations as it is created whenever high temperature combustion occurs, but it is greatly promoted in the industrial world by the presence of rapid fuel-air mixture in the presence of nitrogen and excess oxygen.

NOx is additionally ⅓ of the key components to the greenhouse gas Tropospheric Ozone (O3), which exists 12-20km up from sea level. When NOx is introduced into the air it can interact with Carbon Monoxide (CO) and other volatile organic compounds, where all three can bond and vaporize and enter, suspend in, and pollute the air.

The high temperatures and oxidizing atmosphere required for cement manufacturing are favorable for NOx formation. In Cement Kilns NOx emissions are formed from fuel combustion by the oxidation of molecular nitrogen present in combustion air (thermal NOx), and oxidation of nitrogen compounds found in fuel (fuel NOx). For example, NOx can be created naturally by a forest fire or volcano, but it most certainly happens via combustion of chemical agents on the jobsite where expedience equals a company’s success.

Minimizing the byproduct of NOx during the cement production process is vital and can be mitigated through Selective Non-Catalytic Reduction (SNCR) for the 5 types of Cement Kilns:

| Wet (Long) Kiln | Dry (Long) Kiln |

| Preheater Kiln | Precalciner Kiln |

| Preheater-Precalciner Kiln |

Enhancing NOx Control in Cement Production with SNCR Technology

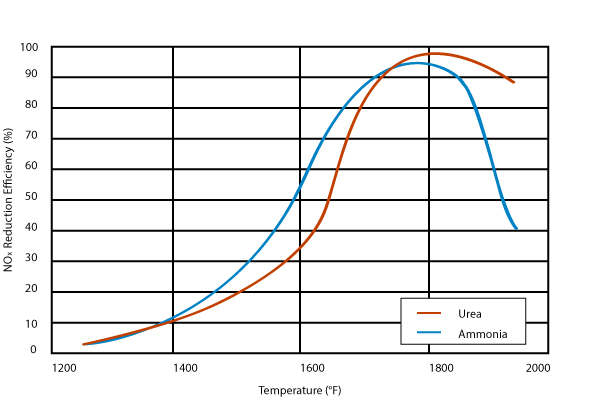

SNCR is the process of injecting ammonia or urea (18-20%) in a water solution into the high temperature zone between 1550℉-2000℉ to oxidize the nitrogen oxide by causing different chemical reactions, which leave nitrogen and water as byproducts that are then discharged as exhaust (via the flue) back into the environment. Typically 90-95% of NOx in flue gas is NO. SNCR technology intercepts a majority of the available chemical reactions to take place and renders them down in high percentages to safer gasses.

Since SNCR is an injection of ammonia-water, no modifications need to be made to your pre-existing kilns. Simply put, you dose the meal mixture with the ammonia solution when it reaches the target temperatures and chemical reaction does the rest. Your factory needs to have space for unloading and storage for the additional materials necessary to transmit the ammonia-water. The machinery needed for SNCR is rather simple: Pump, Pump Skid, Ammonia Flow Control Unit, Convey Piping and Lances, Measurement of Ammonia Feed, Temperature Monitors, and NOx Measurement in Flue Gas Exit.

SNCR efficiency has been demonstrated to reduce NOx emission by up to 70%. Stack Testing is the means for evaluating SNCR efficiency as it tests the levels of NOx released into the environment. To ensure proper SNCR efficiency, a cement plant’s combustion efficiency needs to be regularly monitored to maintain optimum temperatures between 1550℉-2000℉ otherwise the ammonia / urea will not interact properly with the combusting cement mixture.

IAC has SNCR experts on staff, ready to answer your questions about using SNCR and other technologies such as Carbon Capture to reduce greenhouse gas emissions at your cement plant. Call us at 800-334-7431 or submit our simple contact form.

WET CEMENT KILNS

With a Wet Kiln, the raw meal is supplied at an ambient temperature in the form of a slurry or mixture with water. Due to the inclusion of water and low temperatures at the onset, Wet Kilns are very long and narrow, some reaching as long as 200M, in order to allow enough time for proper heating to take place. The heating process commences with the introduction of coal and a variety of waste products (often old tires), which are added to reduce the level of coal consumption.

With Wet Kilns, the SNCR injection process is internal to the kiln, meaning that the ammonia and / or urea is physically added at the appropriate temperature juncture (down the line) to the mix no different than tires and waste products are dropped in about halfway down the kiln where their combustion potential makes the most efficient sense.

Due to the lengthy heating processes, Wet and specifically (Long) Dry Kilns have difficulties maintaining the temperature window of 1550℉-2000℉ for SNCR technology to be effective. However, their processes provide a simplistic means of understanding the process and how SNCR is introduced at the necessary stage.

Interested in using SCNR for your Cement Plant? Read more about IAC's SCNR Technology on our Gas Stream Conditioning page, or submit a request form and one of our sales engineers will contact you.

DRY CEMENT KILNS

The basic Dry Kiln operates with a kiln and a suspension preheater. In the preheater, hot gasses from the kiln and captured heat from the cooling process of the clinker at the end of the kiln are used to heat the raw meal. It enters the kiln hot and is therefore a more efficient and compact process than Wet Kilns.

The raw materials are ground into a meal and fed through a preheater tower and a series of cyclones. Hot gas from the kiln and hot air from the klinker cooler are blown through the cyclones offering an efficient transfer of hot gasses to the raw meal.

PRECALCINER CEMENT KILNS

Precalciner Kilns operate under similar processes to the Dry Kilns but have an additional burner, known as, a precalciner. The additional heat de-carbonates 85-95% of the meal before it enters the kiln. The meal enters the kiln at 900℃ (compared to 20℃ in the wet process), which allows for smaller and shorter kilns and an earlier introduction of SNCR technology. With Dry/Pre-Heater and Precalciner Kilns, SNCR is implemented at lower stages of the pre-heater tower where temperatures are more ideal.

In addition to SNCR technology for NOx reduction, other systems are available: Process Control Systems (<25% reduction), Changing Feed Composition (23-40%), Low-NOx Burners (4-47%), Mid-Kiln Firing (28-59% for Wet Kilns, 11-55% for Dry Kilns), and Selective Catalytic Reduction (SCR) (70-90%).

SNCR has Lower Operating Costs than Other NOx Reduction Methods

In regards to costs of SNCR versus the alternatives, it is important to acknowledge that SNCR is an operating expense driven technology and varies directly with NOx reduction requirements. Operation accounts for, on average, 75% of the costs of the process. Since it is operation based, little costs will be incurred if it is not operational, thus making it very attractive for companies whose production varies season to season.

The cost issues have more to do with the kind and amount of kilns your factory operates and the State regulations you must follow. SNCR doesn’t call for specific kilns or dramatic overhauls to pre-existing machinery, therefore the real questions to consider are your operating temperatures and whether or not you can already store or have to build the SNCR storage space. According to the Institute of Clean Air Companies, SNCR has the broadest range of NOx reduction control from 30-80% and is a great option for any cement factory operating kilns within the 1550℉-2000℉ range. The cost per ton of NOx removed can vary anywhere from $400-3000 per ton of NOx removed. The wide range exists due to different conditions found among different factories. Alternatively, SNCR is dramatically cheaper than the overall most efficient option, SCR.

With SNCR, the levels of ammonia / urea used are remaining costs after initial equipment setup and operation costs (such as electricity). The type of cement being manufactured is going to dictate the ammonia / urea levels as different chemicals react to different elements in different ways. With so many additions being made to the raw meal for differing reasons, tests must determine if SNCR is the best option for your plant in the long run. SNCR is not a “more ammonia / urea equals better results” equation.

The great news is you can easily test SNCR at any plant where the temperatures meet the criteria. With State regulations changing often, SNCR is an excellent option as the process offers the widest breadth of emission efficiency.