3 Things to Consider When Choosing Filter Bags for a Baghouse

1. Temperature

Inlet temperature leading into the baghouse plays a crucial role in any baghouse system. Your baghouse might have bags that are capable of handling the highest potential temperature at the inlet of the unit, or perhaps you operate in a baghouse where temperature really isn’t an issue – then your choice will be quite different (and much easier) from the folks who operate around temperature drops and rises.

2. Chemistry with Gas Stream

Polyester and Teflon are two great examples of fabric filters made for distinct purposes. For example let’s say your system has a highly active/acidic chemical gas stream; Teflon may be a perfect fit for such an environment, as it can withstand chemically active particles and temperatures all the way up to 500° F. Teflon’s fibers’ chemical resistance to dry and moist heat degradation make it an ideal use under severe conditions. Furthermore, the low friction properties of Teflon fibers provide excellent cake discharge. Teflon is most commonly utilized in boiler, carbon black plants, soil remediation systems and incinerators.

3. Moisture

Polyester on the other hand is often referred to as the workhorse of the industry – as it can be utilized in nearly any baghouse system operating from ambient conditions or up to 270°F, and possesses excellent strength and economical characteristics. Testament to this is the fact that polyester is the most widely used needled felt for pulse-jet applications (the most effective type of baghouse system to date). Polyester’s efficient filtration energy absorption characteristics, and resistance to most oxidizing agents, mineral acids and most organic solvents, make polyester a perfect fit for agricultural, woodworking, and chemical applications.

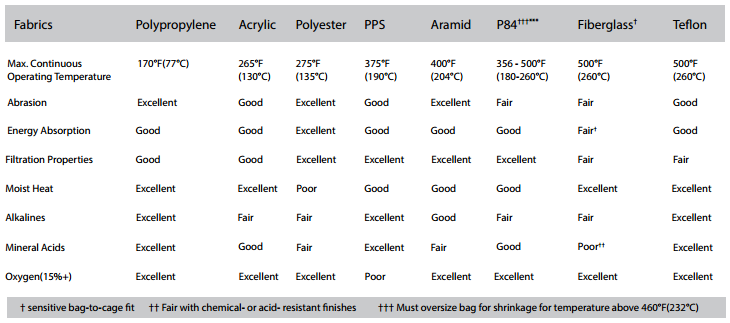

Refer to the table below for an accurate representation of how each filtration fiber interacts with various chemistry/gas stream environments (alkalines and acids), temperature, and moisture.