The Ultimate Guide to Baghouse Filter Bags

Do you ever question the reasoning behind why a filter bag has failed? Or have you never fully understood the importance of certain specifications related to your baghouse? Perhaps you’re not for sure about which baghouse filters work best for your industry.

If so, then keep reading.

Since the Clean Air Act in the 1970s, the utilization of fabric filter baghouses for both process and nuisance dust collection has experienced a 16% compound growth rate worldwide. Growth rates have leveled in the U.S., but maintained themselves in emerging countries. Government and social mandates have brought requirements for larger and more sophisticated baghouse cleaning designs, and more advanced fabric filter bag designs and filter media for use in baghouse filtration.

What does this mean for you?

If you are reading this article, chances are you are familiar with filter bags and dust collectors. Because of the diverse group of industries that fall under the EPA’s air quality standards, it’s crucial to have an understanding of how to comply with these standards. The more you know about how your air pollution equipment works, the more time and money you can save should an issue arise.

Want to know the best part?

We’ve created a comprehensive guide below that details various filter bag designs, dust collection equipment, tips for filter bag selection and more. We believe this guide will serve as an thorough overview and help you become an expert in baghouse filter bags.

Common Names for Baghouse Filter Bags

Since there are so many different industries that utilize dust collection, baghouse filter bags adopt many different names. Sometimes what a filter is referred to can be dependent on the application it is used for, or the material it is made from. The following are a list of names; some you may have heard of and others you may not have. Getting to know this list can instantly help when trying to troubleshoot a dust collector with a co-worker or service provider.

| Common Names for Baghouse Filter Media: | |

|

|

How Baghouse Dust Filtration Works

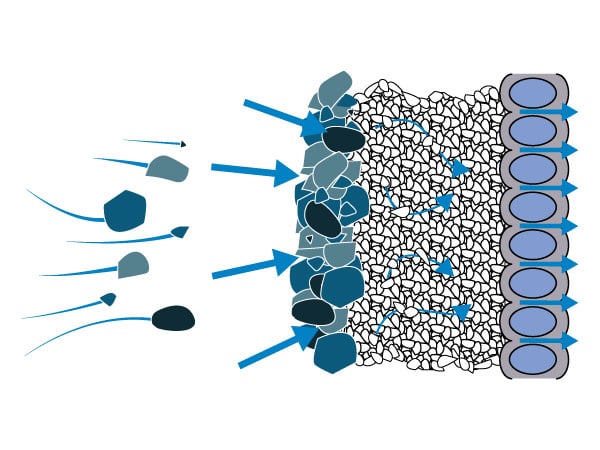

Dry fabric filters, more commonly known as baghouse filters, are used to remove dust from the air by capturing air borne dust(s) suspended in the air. The air is directed using either vacuum suction or pressure into a series of ducts, which run horizontally and vertically from pick-up points at single and multiple plant process and nuisance dusting areas. The dust-laden air is sucked into a main gathering duct trunk line terminating at the air inlet of a baghouse fabric filter.

The baghouse itself is a large housing sometimes designed with multiple chambers. Dust collectors are designed to capture the dust and thus filter the air from particulate laden (dirty air) turning the dirty air into clean air; virtually particle free. Once the air is cleaned, it’s exhausted from the collector’s clean air side back into the atmosphere. Dirty solid particles are captured on the filter bags surface, while the gases being filtered pass through the filter bags media. This bag media is called “filter media” and will be discussed later.

Baghouses can automatically clean the filtered particles off of the filter media based on a periodic need to clean the filter bags media. This is called regenerating the filter bag media's permeability, which removes enough compacted dust cake to allow air to flow again at a low (<6” W.G. static loss) restriction (static loss) across the filter media.

The system depends on a Fan or Blower to either pressure (push) or vacuum (suck) the air across the filter bags’ media. This means the filter bag's media has a dirty side and a clean side. The dirty side intercepts, filters, and compacts the dirty air stream gases, while the clean side has contact with clean air stream gas as it passes through the media.

Now let’s get into some details.

Popular Types of Baghouse Filter

Cleaning Mechanisms

Since baghouses must periodically clean themselves by purging the dust off of the fabric filter bags to regain permeability to support design air flow, it is time to identify the most popular types cleaning mechanisms:

- Pulse Jet: High Pressure compressed air; 80-100 psig; dust collects on the outside

of the bag. - Pulse Jet: Medium Pressure compressed air; 50-55 psig; dust collects on the

outside of the bag. - Reverse Air: Reverse Gas flow at 6-20” W.G. Pressure; dust collects on the inside

of the bag. - Reverse Air: Reverse Gas flow at 3 to 15 psig; dust collects on the outside of the

bag. - Shaking: Shaker style, using mechanical agitation to get up a sinusoidal wave over

the bag’s length. Dust collects on the inside of the bag.

But that’s not all.

In addition to the above, there are also combinations of Reverse Air / Shaking and Acoustical Energy

cleaning designs manufactured as baghouses.

Two other baghouse design distinctions that are important to be familiar with are inside bag dust collection and outside bag dust collection. Inside bag dust collection occurs when the dust is collected on the inside of the filter bag media’s surface. A filter tube with the dirty air flows into one end of the filter tube; the dirty side is inside the tube; and the clean gases exit to the outside surface area of the tube. In outside bag dust collection, dirty gases flow from the outside of the filter tube, through the media. Clean gases exit to the inside and out through the bag tube’s inside surfaces. Dust is collected and remains on the outside of the filter bags media.

What about the filter bags that are used in dust collectors?

Fabric Filter Media Designs to Know About

Types of baghouse filter media designs include traditional filter bags with support cages, plus filter cartridges:

- Tubular Felted Bags: Open top; closed bottom; mounted to wire cages. Can mount from dirty side or clean side of baghouse on clean air plenum design. Cleans best at 90-100 psig air.

- Tubular Woven Bags: Open top; closed bottom; mounted to wire cages. Can mount from dirty side or clean side of baghouse on clean air plenum design. Cleans best at 90-100 psig air.

- Envelope Bags: 1” up to 2 ½” opening x 36” to 60” sq.; felt media and woven media are utilized. An inside support frame or high loft medium is used to maintain an open area across the bag’s depth.

- Cartridges: This filter design uses a tightly packed pleat counts (5 times the pleated elements pleat count per inch) and typically uses paper, synthetic/organic medias, and lightweight felts to collect fume, light inlet grain loading, powders, and plasma table dust. Top load, flanged, and bottom load styles are available.

- Pleated Elements: Elements are pleated using between 30, up to 60, pleats in a 6” dia. tube; pleat depths are from 1” up to 1 5/8” depth, both molded rubber and metal tops are used. An inner core made from metal or polypropylene is used. Medias range from 8 oz. spun polyester to 10 oz./sq. yd. Nomex. Solid polymer or metal caps are used as element bottoms. Top load and bottom load designs are available.

- Special High Loft Envelope Filter Block: Constructed from proprietary cindered materials.

Filter Bags for High Pressure Pulse Jet Cleaning (70-100 psig):

Bags are felted media, and can utilize all available types of media, including woven and special woven fiberglass for use in pulse-jet cleaning baghouse designs

Filter Bags for Medium Pressure, High Air Volume, Pulse Jet Cleaning:

Special inlet baffling is designed to split the inlet air as stream to a 60% upward flow and 40% downward airflow. This Pulse Jet baghouse design can accommodate 6 meter to 10 meter long filter lengths, ranging from 5.35” dia., up to 6” dia., and 2-piece cages. This baghouse design is typically applied to filter gas volumes greater than 140,000 ACFM and up to 2.5 million ACFM. Both on-line and off-line cleaning air offered. All generic filter media can be utilized in this medium pulse fabric filter design.

Filter Bags for Reverse Air Cleaning:

Collect dust inside the bag; use all popular media; often have anti-collapse rings and D-cap tops; and utilize a reverse flow of air, while the bags are at null, to backwash the dust down through the inside of the bag. Inlet velocity ranges from 250 – 270 FPM. Bags are cleaned off-line at null FPM. Air to cloth ratios are 2.0:1 to 2.5:1. These are tubular bags mounted vertically.

Filter Bags for Traveling Reverse Arm Rotating Air Cleaning:

Mounted onto wire cages. These bags collect dust on the outside. Filter media is felted and uses a gentle blow back fan air on PD Blower air to clean multiple bags as the rotating arm sweeps around the top of the tubesheet, inside the clean air plenum. These are tubular, or oval, bags mounted vertically.

Filter Bags for Shaker Cleaning:

Collect dust on inside; usually constructed from a woven media. All generic filter media can be used, although generally felts and anti-collapse rings are not used. Bags are installed with some slack in length, so that the shaker, if it provides for bag lift (amplitude), can raise and turn the bag in a rapid shaking motion to develop a clean motion along the media surface, called a “sinusoidal wave”. Inlet velocity through the bottom bag connection, called an orifice, is generally designed to be below 250 – 270 FPM. Air to cloth ratios are 2.0:1 to 3.0:1 and bags require off-line cleaning with air velocities at “null” (zero FPM).

🛠️ View our video on how to properly install a filter bag in a baghouse

Tubular Filter Bag Designs, Sizes and Tailoring

There are many different dry fabric filter bag designs that can be manufactured using a range of generic filter media fibers, sizes and tailoring. The selection of generic fiber is dependent on the baghouse’s application at the manufacturing plant’s facility. Common application criteria used to select the type of generic fiber used in the filter media are: gas stream; chemistry; temperature; particle size and micron size range; EPA emission requirements for the type of dust and size of the APC system; percentages in the gas stream of sticky materials; and moisture by volume; and dew point considerations.

| Common Filter Bag Diameters Flat Width (FW) | Sizes Supplied to the US Market: |

|

|

Common Filter Bag Lengths:

- High Pressure Pulse Jet Cleaning; 18” up to 192” length

- Medium Pressure Pulse Jet Cleaning: 6 meter up to 10 meter length

Filter Bag Top Construction:

- Side Load: raw edge top (3” longer than split collar cage length)

- Top Load: snap band; double beaded

Filter Bag Bottom Construction:

- Single-ply felted disc bottom

- 3” bottom; double-ply wearguard

- 5” wear cuff with 2” overhang below bag disc bottom

Grounding wire to meet NFPA77; 2 301SST braided ground wire, sewn in 180 degrees apart at filter’s snap band.

Characteristics of Filtration Fibers

Acrylic Fibers

Acrylic fibers are man-made fibers in which the fiber forming substance is any long-chain polymer composed of at least 85% acrylonitrile units and the remainder of copolymer. Acrylic is non-thermoplastic.

Orlon*(Dupont); Acilan*(Monsanto); Creslan*(American Cyanimid); Crylor*(Crylor SA); Zefran*(BASF); and Draylon-T*(Bayer) are trade names used by various produces of acrylic fibers.

Draylon-T* (or equivalents), a homopolymer (100% acrylonitrile), is a widely used acrylic for high-pressure cleaned and needled felts. Fiber cross-sections are dumbbell shaped and surfaces are striated. Diameters are typically 15 to 35 microns. Where polyesters are not suitable because of potential hydrolysis, acrylics offer a combination of abrasion resistance and resistance to wet head degradation, particularly under acid conditions. Homopolymer felt is a candidate for hot gas application of less than 284°F. Temperature resistance of copolymers is less: 240°F.

Acrylic felts are used in drying raw flour, coal, gold, and copper ores; galvanizing; and low temperature flue gas applications. Polyester is superior for most dry heat applications.

Aromatic Polyamide (Nomex)

Nomex nylon was a propr ietary (patent has expi red) aromaticpolymide (Aramid) linked structure developed by E.I. DuPont de Nemours, for application requiring dimensional stability and high heat resistance. Nomex is a non-thermoplastic, so it does not melt, but at temperatures above 700°F, degradation sets in rapidly. In heat up to and including 400°F, this fabric may be used satisfactorily as long as there is no acid dew point problem.

Nomex is unaffected by small amounts of water vapor and high temperatures. When exposed to saturated steam at high temperatures, Nomex will progressively lose strength. However, it withstands these conditions better than many other fibers.

Nomex withstands the attack by mild minerals and inorganic acids, mild alkali and most hydrocarbons. It is unaffected by florins and gases from metallurgical and rock processing operations. However, high active oxidizing agents, such as sulphur oxides, will rapidly degrade Nomex. The single biggest use for Nomex, needled felt, is asphalt batch plant dryers and drum-mix plants. Other uses include raw and finish mill grinding on cement plants, carbon bake, clinker coolers and many other hot gas processes.

Polyester (PE)

A manufactured fiber in which the fiber forming substance is any long chain synthetic polymercomposed of at least 85% by weight of an ester of a dihydric alcohol and terephthalic acid. This material is a thermoplastic.

Fiber is available under various trade names: Dacron*(duPont); Enka Polyester*(American Enka); Fortel*(Fiber Industries/Celanese); and Kodel*(Eastman Chemical). Polyester is the most widely used needled felt for pulse jet applications.

Polyester is superior to most synthetics in dry heat installations, but it is not comparable to Teflon or Nomex. Recommended operating temperature is 275°F maximum.

Note: under moist near-saturation heat conditions (between 160°F and 210°F), polyester is inferior to other synthetics. The fibers will go through hydrolysis, weakening the fabric.

PE provides good resistance to most oxidizing agents, mineral acids and most organic solvents except high concentrations of sulfuric, carbolic and nitric acids. It resists weak alkalis. However, strong alkalis at high temperatures will dissolve the fabric.

Polyester fiber makes an excellent filter fabric with efficient filtration and good energy absorption characteristics. It is used in agricultural, woodworking, chemical and other applications where chemical and mechanical characteristics are compatible. As needled felt, it is available in 12, 16 and 18 oz/yd2 versions. The use of a 12 oz/yd2 should be reserved for non-critical applications handling large particulate. Spun-bonded media is available in plain water/oil resistant (TR), metalized-antistatic (ME) and with laminated PTFE membrane.

Polypropylene (PP)

Polyolefin is a manufactured fiber in which the fiber forming substance is any long chain synthetic polymer composed of at least 85% by weight of olefin units.

Herculon (Hercules) and Reevon (Phillips) are trade names used by various producers of polypropylene (PP) fibers. The fibers combine excellent resistance to most acids and alkalis, plus high strength. It has one of the lowest specific gravities of any synthetic fiber, and is one of the most economical synthetics (about the same price as polyester). PP is a good choice for replacement of cotton in low temperature applications.

PP absorbs no moisture and provides excellent cake discharge and resistance to blinding. Filtration efficiency is not quite as good as polyester. Polypropylene has very low heat resistance, even less than cotton, and should not be exposed to prolonged temperature of over 165°F. Since it does not absorb moisture, its degradation characteristics in dry heat and moist heat are virtually the same. Within its limited temperature range, polypropylene provides good resistance to mineral and organic acids. It resists alkalis, reducing agents and organic solvents. It is however, soluble at 160°F in chlorinated hydrocarbons.

P84 (Polyimide)

P84 is a proprietary fiber produced by Lenzing in Austria. P84 is a nonthermosplastic, and in 100% form, may be used for temperature of 500°F. Its fiber is highly convoluted, having a high surface area-to-diameter ratio.

Extensive testing has shown that P84 fabric approaches Gortex in efficiency, but has all of the advantages of a needled felt. It may be layered on top of lower cost fibers to provide the benefits of the base fiber, but at lower costs than a 100% version of the P84 felt. Composites generally have a 4 oz./yd2 P84 fiber layer, needled to a 12 oz/yd2 carrier base. P84 is readily available in 14 oz weight, but other weights are available.

P84 needled felt and composites are used in many industrial applications where high efficiency is required. Examples are: gold and copper ore processing, incinerators, boiler and various chemical processes.

Teflon

Is a proprietary fluorocarbon fiber manufactured by E.I. DuPont. It is composed of long chain carbon molecules in which all the available bonds are completely saturated with fluorine. These strong carbon-to-fluorine bonds create fibers that are exceptionally stable to both heat and chemicals. Teflon is the most chemically resistant fiber used in conventional dust filtration.

Teflon is not affected by any known solvents except some prefluorinated organic liquids at temperatures above 570° F. Exposure to temperatures above 550° F will cause some decomposition, although it is slow to develop. Teflon bags shrink when exposed to high temperatures, especially in length.

The low friction properties of Teflon fibers provide excellent cake discharge. In addition, Teflon fibers chemical inertness and resistance to dry and moist heat degradation makes it ideal for use under severe conditions.

Teflon needled felt is extremely expensive. Recently, a lower cost version, Tefaire*, has been introduced. This felt is a blend of 85% Teflon and 15% fiberglass fibers. Commercial uses are limited to extreme chemical environments where the advantages of Teflon fibers’ great chemical resistance outweighs cost disadvantages. Some boilers, carbon black plants, soil remediation systems and incinerators have been equipped with Teflon products.

Glass

Glass fiber is a product of fusion, a non-crystalline silicate analogous to other fiber polymetric materials. Selected silica sands, limestone, soda ash and borax or other ingredients are melted at about 2,500° F, and the mixture is extruded through spinnerets. The resulting filaments may be drawn while still molten and later twisted and plied into filament yarn.

Or, the extruded glass may be drawn and broken by jets of compressed air into lengths of 8 to 15 inches. The fibers are then treated with a lubricant which is of great importance in the durability of the eventual fabric. Following drying, the fibers are processed much like the more conventional fibers.

Woven fiberglass and felted fiberglass media are available for high energy cleaned fabric filters. These are specialty products that are used for very specific applications involving high (up to 500°F) temperatures, usually in the presence of oxidizing agents.

Some common trade names for woven fiberglass are GL65 Tri-Loft* and FL57 Hi-Loft; other companies have similar products. Available weights are 16 to 22 oz/yd2. Huyglas* felted fiberglass medias are available in a variety of weights , from 14 to 27 oz/yd2 . Bag/cage fit and support is very critical. Check with the vendors involved for specific recommendations.

Woven fiberglass in particular is very easy to damage, and is not as efficient as other media. Felted fiberglass tends to be heavy and difficult to handle. Suitable applications for this material are limited. Consult IAC engineering before using these products for any applications.

Ryton (Polyphenylene Sulfide)

Ryton (Phillips); commonly called PPS; is a long chain synthetic polysulfide, with at least 85% of the sulfide linkages attached directly to two aromatic rings. Standard fiber is 3-denier. The resin was developed by Phillips Petroleum in 1973.

Ryton is resistant to sulphur oxides and is used for high-temperature gas streams up to 360°F. Gas stream oxygen content should not exceed 15%. Ryton does not hydrolyze and has flame retarding characteristics.

Typical applications are industrial/municipal solid waste incinerators and coal-fired boilers

Tips for Selecting the Proper Baghouse Filter Bags

As a baghouse OEM, one of the most important Baghouse Equipment IAC design criteria considerations is the proper selection of both the bag’s filter media and the bag’s size / tailoring. To select a proper bag filter media as a baghouse OEM and as baghouse owner in the market to purchase bag replacements, you need to determine the following information:

- Compare baghouse application / process to filter media application selection chart by temperature and chemical resistance.

- Evaluate previous IAC job dust handling experience to select suitable internal can and interstitial velocity ranges.

- Once internal velocities ranges are agreed upon, then final air to cloth ratio and filter bag length can be calculated.

- Filtration efficiency selection in terms of outlet dust emission requirements to meet air permit is revisited based on actual internal velocities, air to cloth ratio, and bag length. This final analysis and review is used to determine if special media surface treatments or PTFE membrane is required to insure success in meeting filtration efficiency and maintaining a DP range of between 2.5” WC to 4.5” WC.

- Determine special application design requirements for ground wire, bottom wear guards, and special sewing / needle hole close-offs. At this point in your developing final filter bag selection and specifications you will have determined the following bag design criteria:

- Fabric Selection

- Bag Length

- Bag Tailoring

- Surface Treatments

- PTFE Membrane option

- Next, here are some helpful tips to ensure you receive the filter bag you have specified and have placed on order

- Specify only filter media produced in the USA

- Specify specific fiber suppliers; example: Nomex – E.I. DuPont

- Your PO should state no off-shore media or membrane allowed

- If a PTFE membrane is being used, state the vendor’s membrane you want to use clearly on your PO, plus add made in USA only.

- If you are ordering a fiberglass media, be sure to specify that only Burlington, Menardi, or JP Stevens media and finishes are acceptable.

Design and Accessories That Affect Bag Performance

All successful baghouse performances share common design, accessories, and attention to quality details. Below is a list of equipment, components, and quality control specifications that when specified by the baghouse OEM and end user as mandated / necessary design / supply requirements will insure a successful baghouse performance and extended filter bag life.

Cleaning System Design / Components

- 1 ½” Double Diaphragm Pulse Valves

- Min. 100 psig of available Compressed Air Cleaning Energy

- Demand Cleaning based on Dual Set-point DP Switch or DP Transmitter

- Air Header Pressure Transmitter

- Not more than 17 bags in one row to be cleaned

- Pulse / Solenoid Valve Setting: between 90 to 120 milliseconds

- Cleaning Interval: max. 15 seconds when cleaning

- Smart Timer Panel: to start cleaning next row from last row cleaned on prior cleaning cycle

- ¼” Air Tubing Distance form Solenoid Valve to Diaphragm Valve; NTE 8 ft.

- 6” dia. Air Header

- Timer Board’s terminal strip positions will have only (1) solenoid valve landed per each (1) position on terminal. Timer will fire only (1) solenoid per position.

Material Handling Design / Equipment

- Min. 60° Slope Hopper

- Min. 8” Discharge Opening

- Ladder Vane Inlet Baffles (min. 3)

- Hopper Hi-Level Indicator

- Hopper Vibrator Mounting Channel

- Hopper Poke Holes

- Hopper Rapper Plate

- Hopper Inspection Clean-out Door

- Continuous Material Discharge

Bag / Cage / Tubesheet Assembly Design

- Snapband top bag to Tubesheet attachment design

- Laser cut Tubesheet Holes

- Min. 3/16” thick Tubesheet

- 3” Bag Bottom Wearguard

- PTFE Membrane Filter Media

- n. 12 wire cage for 5.25” to 6” dia. 10 wire 4.5” to 5.0”

- Bag Pinch: min. ½”; max. 5/8”

- Steel Cages to be specified no burrs; sharp edges and ring spot welds to be positioned against a vertical stringer wire

- Venturis are required

- Blow Pipe Holes; 1/16” tolerance to center of bag; radial holes NTE 5% off of staright vertical

- 100% Galvanized Cages

Conclusion

There you have it! You are now on your way to becoming a expert in baghouse filter bags. If you’d like to expand your knowledge even further we can send one of our engineers to your facility to conduct a workshop custom fit for your equipment and staff. Here at IAC we value providing everyone with knowledge around dust collection; whether you are a customer of ours or not. Our values and experience are the foundation to IAC being in business since 1987. When you use IAC for your baghouse systems and parts you know you’re doing business with an industry leader in dust collection experience and expertise.