Dust Collector Remote Monitoring: IAC's Smart Plant GEN 4

The Industrial Internet of Things (IIoT) is revolutionizing the way companies monitor their process operations. Dust Collector remote monitoring, in particular, is becoming increasingly popular among company executives and plant maintenance personnel because of its benefits. With the help of industrial IoT remote monitoring, companies across a wide variety of industries can improve their operations, streamline their production processes, increase safety for plant personnel, and reduce costs.

IAC's Smart Plant Gen 4 Remote Monitoring Systems for Dust Collectors and Baghouses

IAC was an early adopter of industrial dust collector remote monitoring systems. As an original equipment manufacturer and services provider, we saw how the technology could benefit our customers in numerous ways. Our new turnkey Smart Plant™ Gen 4 Remote Monitoring systems make it easier than ever to "Connect, Collect, Predict, & Improve" operations of your baghouses, dust collectors, and ventilation system equipment.

Smart Plant™ Gen 4 Technology Developed by IAC is a Universal Gateway Product That Can:

• Connect up to 8 Analog or Digital signal (Any brand) to the Cloud via secured one-way cellular signal

• Upgrade most any baghouse’s controls and cleaning function – Up to 240 baghouse rows

• Alerts via SMS text or email for any plant measurable

• Completely scalable and modular to easily add to any plant equipment or Model

• Confirm equipment is operating correctly in the safest way possible...remotely!

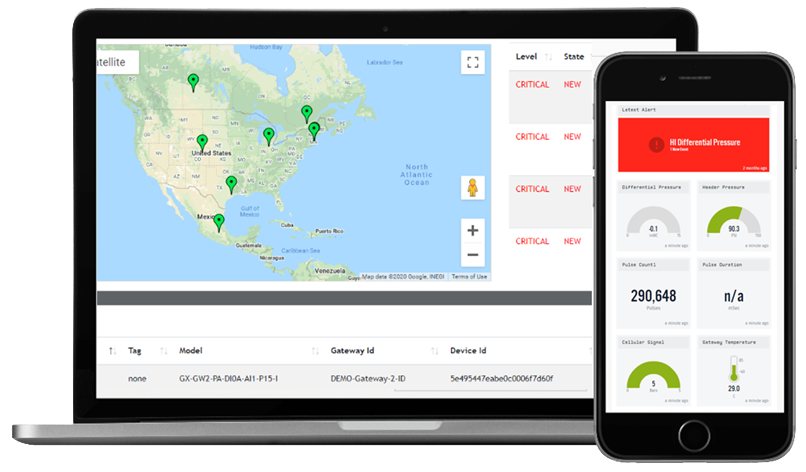

Smart Plant™ users are equipped with preventative and predictive maintenance in the palm of your hand at the fraction of the cost of the large IoT companies. Our turnkey, cloud based industrial IoT system allows personnel to remotely monitor equipment operation from anywhere around the globe via any smart phone, computer, or tablet.

Get Real Time Reporting with Unlimited User Access

The IAC Smart Plant™ GEN 4 systems bring the ultimate technology to record process and air cleaning data outputs on a near real time bases direct to the operators and management smart phones, desktops, and/or tablets. Offering unlimited user access to avoid paying those expensive by user licensing fees. This plan starts with the equipment’s sensor, which are part of any automated process equipment as well as the dust collection system.

Typical Smart Plant™ Gen 4 Instrument List (Sensors) Providing Digital and/or Analog Signals:

| Compressed Air Usage Transmitter | *Now available in Battery Powered & Wireless |

| Pressure Transmitter | |

| Vacuum Transmitter | |

| "DP" Transmitter | *Now available in Battery Powered & Wireless |

| Thermocouple/RTD | *Now available in Battery Powered & Wireless |

| Airflow | |

| Broken Bag Detector Transmitter | |

| Level Indicator | *Now available in Battery Powered & Wireless |

| Vibration | *Now available in Battery Powered & Wireless |

| RTD - Bearing or Ultrasonic | *Now available in Battery Powered & Wireless |

| Speed Switch | |

| Open to Close | |

| Energy Monitoring | *Now available in Battery Powered & Wireless |

| Any Analog / Digial Input | *Now available in Battery Powered & Wireless |

The Smart Plant™ IoT hardware do not connect to existing plant Ethernet or WiFi networks in any way. Cloud connectivity is provided through a fully isolated cellular connection providing Smart Plant™ users an easy way to become equipped with preventative and predictive maintenance in the palm of your hand. The cloud based industrial loT system allows personnel to remotely monitor equipment operation from anywhere around the globe, all the while maintaining a 100% secure communication system. Cellular coverage is available in over 130 countries worldwide.

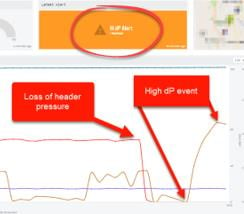

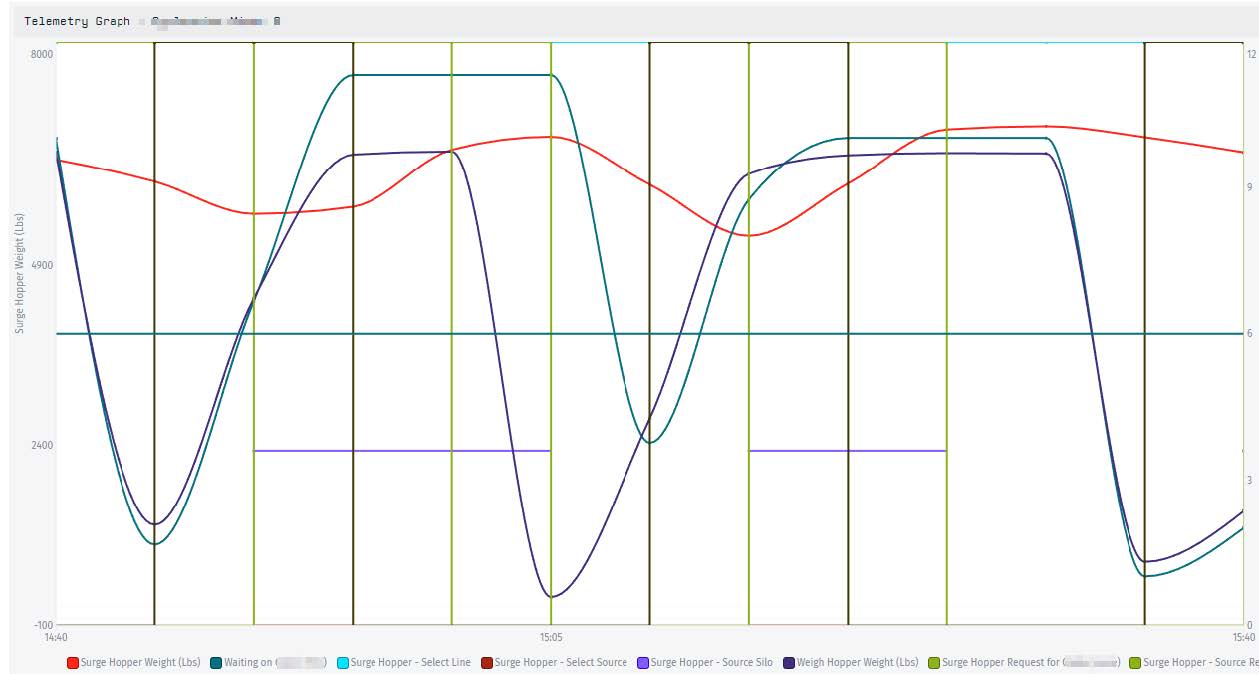

The Smart Plant™ delivers warning and escalating critical alerts as a text or email message. As operational data is gathered, users can track and alert against costly vibration and bearing issues continuously not Quarterly/Annually using our Smart Plant™ wireless options. With additional customer engineering, IAC can provide process visibility at a fraction of the cost of more and more complex standalone hardwired systems. Minimizing exposure and safety concerns with continuously monitoring higher risk locations within the plant. Providing you with the ability to visualize the plant processes and find production bottle necks, allowing processing/ operations to increase up time and maximize profitability.

|

What Can IAC's Smart Plant™ Remote Monitoring Service Do For You? |

|

Alert (text, email) on high alarm conditions, know when solenoids fail, alert high temps, count cleaning pulses |

|

|

|

|

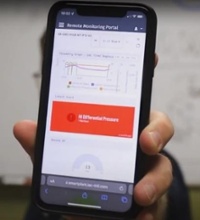

Receive warning / critical alerts on your phone |

Not when, not if, but a failure has occurred |

Track and alert against vibration using Smart Plant+ wireless options |

|

With additional (custom) engineering, IAC can provide process visibility at a fraction of the cost of more complex hardwired systems. Providing the ability to visualize the plant processes and find production bottlenecks, allowing our customers to increase manufacturing and profitability. |

|