Frac Sand Production Market

Operational Services Growth Opportunities

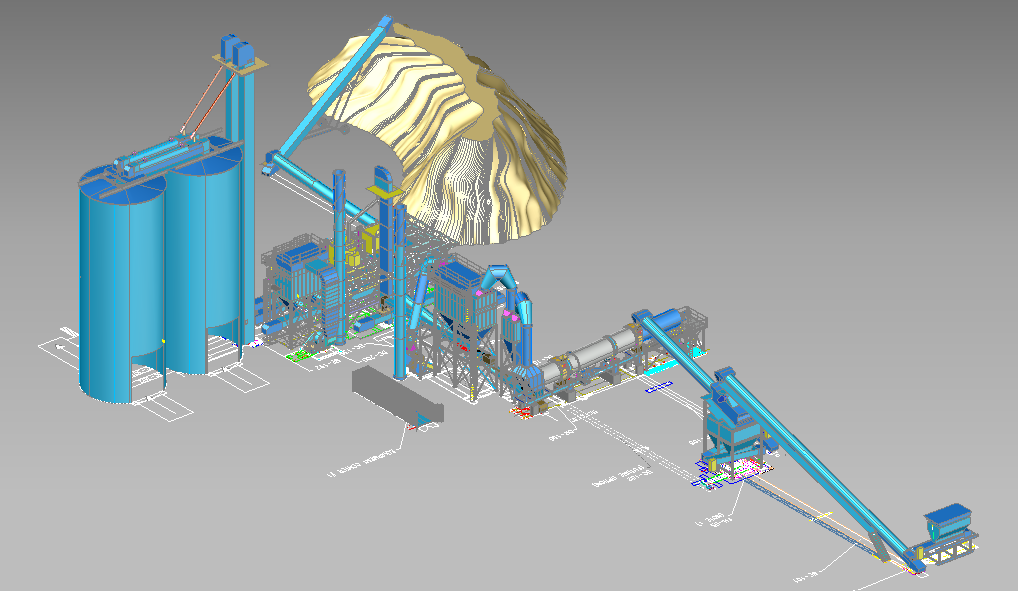

Mission, KS – November 2018 – IAC is a leader in the design and construction management of turnkey Frac Sand Plants for the natural gas and oil frac sand production industry. IAC has the unique capabilities, experience and expertise to continue to capitalize on the designing and building of Frac Sand Plants as well as capitalize on the opportunities in the after-market space which includes parts, maintenance, support, and plant optimization.

Offering full plant, post start-up, and operational services furthers the turnkey, problem-solving, high value approach which has been a hallmark of IAC’s success. Optimizing and maintaining communication with the customer provides insight into future projects and design/build opportunities prior to a formal bid process.

Current Market Potential for just the Permian Basin is estimated at more than $30 million in Year 1 and in excess of $6 million annually thereafter. This does not include estimates for the growth opportunities associated with providing plant management or additional services.

Leader in EPC, Parts, and Service for the Frac Sand Industry

For more than 30 years, IAC has served as a comprehensive solution provider to industrial clients for capital equipment needs by providing turnkey plant, engineered systems, solutions, parts, and services. IAC seized the opportunity to be a comprehensive solution provider for larger capital projects that its EPC (Engineering, Procurement, and Construction) services deliver. IAC’s growth to the premier provider of turnkey Frac Sand plants started through its relationship with Preferred Sands. Given its leading expertise in EPC for Frac Sand Plants, IAC will continue to grow into multiple vertical industries as a go-to, rapid-response solution provider. Factors to support this approach include:

- Many of the industries IAC supports with parts and services have demonstrated an interest and have already engaged IAC in EPC and engineered systems projects.

- The rapid growth of the Frac Sand industry in Texas required owners to construct plants in a non-engineered, non-standard, non-optimized fashion. Many plants today are experiencing a high degree of equipment failure, low plant utilization, and minimal sustained throughput levels or full utilization of their capacity, requiring support, retrofit and optimization.

- Frac Sand Plants are operated at an aggressive pace based on demand for frac sand for initial, exploratory drilling. Given the abrasive nature of the sand, rocks, trees stumps, and other materials processed by the Frac Sand Plants, they have a near constant need for upkeep, maintenance, and repair.

- Work force utilization and training has severely impacted current frac sand plant operators. There is a need for experienced operators and control automation to assist in dealing with high turnover of the under skilled work force.

Integrated EPC, After-Market Parts & Services Provider

Based on these and other factors, the Frac Sand Industry has a heightened and immediate need for a business with the knowledge and experience to design and build new plants, re-engineer existing plants, train, maintain, service, and optimize their facilities.

After-Market Parts

As an experienced industrial OEM provider for multiple sectors and product types, IAC is uniquely positioned to support Frac Sand plants through the application of their existing products, engineering talent, production capabilities, and field service teams. This integrated solution-provider approach, particularly with industrial parts and services, is a core capability of IAC. The workforce at IAC has the breadth and depth of experience to be able to be the go-to, rapid-responder for maintenance and repair of Frac Sand Plants.

Training Services

Upon the completion and commissioning of the Frac Sand Plant, IAC would develop and provide operations and maintenance best-practice client training. IAC is already a high value solution provider and were recently asked to present on frac sand optimization to the industry. IAC has secured multiple contracts to train and support plant workforce development.

Plant Optimization & Consulting Services

IAC has developed a process for assessing, defining and measuring performance, then identifying opportunities for optimizing plant production and efficiencies. The combination of data and control interface provide advanced analytical tools to determine optimum operating conditions under change in feed or process conditions. IAC is skilled in assessing current and future design states and building control and logic to optimize the utilization and output of plants industry wide.

Outsourced Operations & Maintenance Services

For clients who do not have the resources or who want the best expertise available, IAC will provide outsourced operational and management services, meaning IAC would operate the Frac Sand Plant for the client. Operational Services are in demand and competitive intelligence shows this to be a high margin opportunity.

Since developing this overall Operational Services strategy, IAC has proposed these offerings to several clients, resulting in a number of contacts. This has positioned IAC as a leader in numerous industries while the concentration in the Frac Sand Production market has established IAC as the clear leader in integrated frac sand plant solutions.

About: IAC and its subsidiary, Adelphi Construction, LC is a 33-year-old EPC Contractor providing OEM Air Filtration & Material Handling Products and Services, and other unique OEM Equipment such as patented Sand Dryers for the Frac Sand Industry. It has 300 employees located in USA, Mexico, Brasil, and Argentina, annual sales of more than USD $250 million. For more information about IAC please visit our website at iac-intl.com.