Importance of Discharge Valves

In previous tips of the month videos we’ve discussed how ventilation works in a baghouse system and the importance of differential pressure. Now we shift our focus on the discharge valve and the role it plays in a ventilation system.

A quick recap on how air flows through a baghouse; there a two areas in the system that pull a negative, resulting in air being pulled through the vent point.

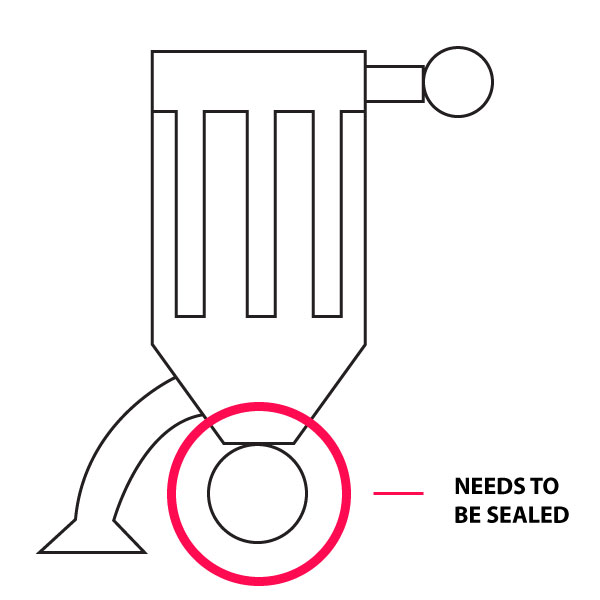

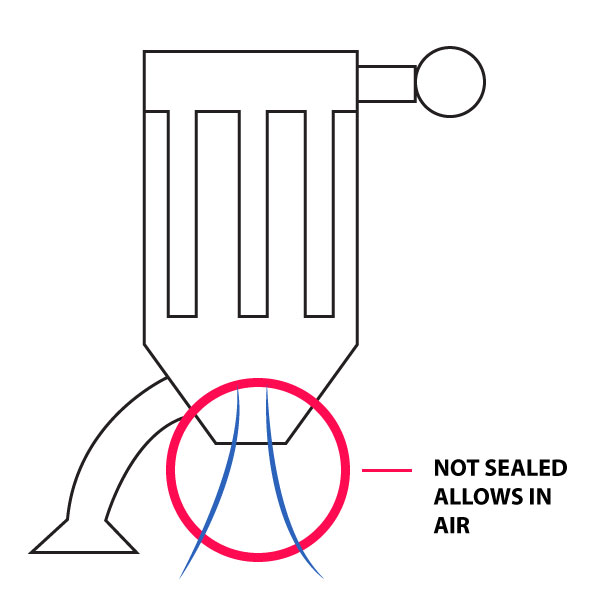

That leads us to the discharge valve on a dust collector. Rotary Valves, Double Dump Valves or any other discharge valve made for a dust collector, should be designed to function without allowing air back into the system. However, some people make the mistake of wiring their valve open thinking it will discharge at a faster rate.

This couldn’t be farther from the truth.

Leaving the valve open actually results in less material begin discharged because that area of the system is now allowing air to enter it. This mistake also leads to a reduction in ventilation where it is needed in the system.

Is your discharge valve in good shape?

If you have a Rotary Valve you want to check that the blades are not worn down. If you have a Double Dump Valve be sure to check that it is moving properly.

If you’re not sure if your valve is working properly and you need assistance, we’re here to help! Contact us today to speak with one of our engineers.