Properly Monitoring Baghouse Differential Pressure

In last month’s video in our Tip of the Month video series, Luis Castano discussed understanding differential pressure. If you haven’t seen the previous video, you can go back and view it here. Now that we know what differential pressure is, how can we properly monitor the number to improve our system?

Controlling Differential Pressure

Differential pressure is a measurement of the amount of dust present on the filters inside of a baghouse. In order to control this number you want to determine how often to clean your system. Cleaning a dust collection system too often can result in the dust cake not building up on the bags, making them susceptible to moisture. Not cleaning your baghouse enough will shorten the life of your filter bags, resulting in the air flowing through the system to not filter properly.

The Ideal Number

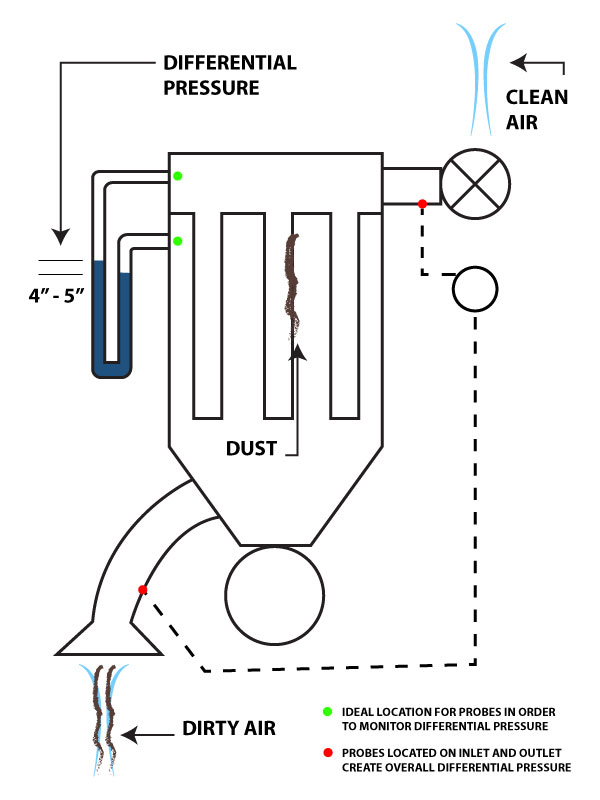

When taking the cleaning cycle into account the ideal number for differential pressure is likely to be around four to five inches. One thing to consider is if your system’s probes are located on the inlet and the outlet as seen in the illustration above. If the probes are located on the inlet and outlet this creates overall differential pressure, which is different from differential pressure as it takes into account mechanical losses. In order to monitor differential pressure the right way you want your probes located on the clean and dirty side; represented by the green dots in the illustration.

Do you have questions about monitoring your system’s levels? Call us today to speak with one of our engineers and we’ll get you on the fast track to getting the most out of your baghouse.