Cost Effective Ways to Improve Your Pulse Jet Baghouse

If you’re thinking about replacing your pulse jet baghouse due to failing performance but don’t have the funds to do so, read on. Many times you don’t need to replace a low performing pulse jet baghouse, as there are some cost effective steps that can be taken to keep the baghouse running efficiently.

Installing filter bags properly

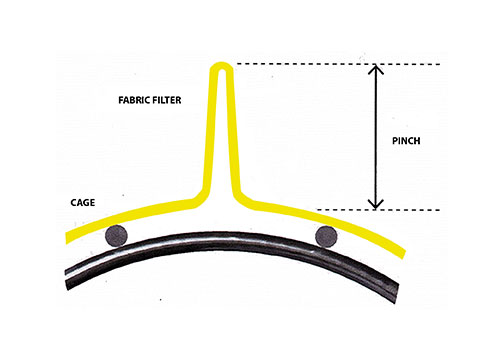

Making sure the filter bags are installed correctly is a cost effective way to increase the life of the bags. An often overlooked technique for installing filter bags is utilizing a pinch in the fabric filter. Sometimes bags can become too loose on the cage resulting in limited collection efficiency and/or premature failure. By pinching the fabric of the bag you will tighten the fit to the cage which will allow you to maximize the performance and life of your bags. To determine the proper pinch you need to subtract the cage circumference from the bag circumference and divide the result by 2. Use the chart below to determine the amount of excess fabric to allow based on the bag type, and what the recommended support cage would be.

| Fabric | Pinch | Recommended Support Cage |

|---|---|---|

| Felt | 0.25″-0.75″ (6.4-19 mm) |

Any |

| ePTFE membrane on felt |

0.0625″-0.3125″ (1.6-7.9 mm) |

Any |

| PPS | 0.25″-0.5″ (6.4-12.7 mm) |

Any |

| P84** | 0.125″-0.375″ (3.2-9.5 mm) |

20-wire |

| Fiberglass | 0.125″-0.375″ (3.2-9.5 mm) |

20-wire |

Automate the pulse cleaning cycle

Creating an on demand cleaning cycle for your baghouse will optimize the energy efficiency, saving compressed air and operating costs. Using the combination of a Photohelic pressure switch and gauge adds the ability for an automated cleaning cycle. This Photohelic combination allows the differential pressure to be automatically monitored in order for it to determine when to begin the pulsing process. You can adjust the settings of the equipment so that when the differential pressure becomes too high the cleaning cycle begins, and when the differential pressure lowers to a desired point the cleaning shuts off. Not only does the switch and gauge save energy, it saves your staff time from having to constantly monitor the differential pressure levels and manually operate the cleaning cycle.

Use pre-coat powder

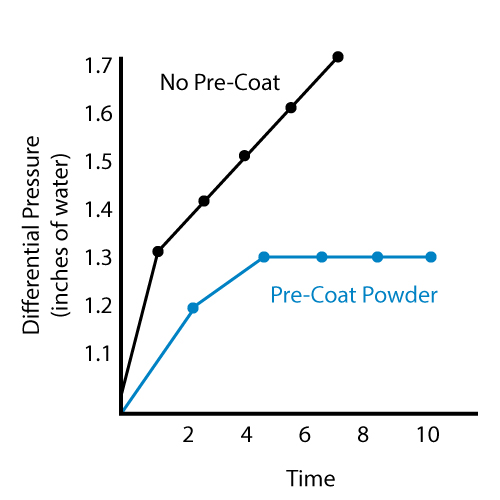

Applying pre-coat powder when installing a new filter bag will improve filtration efficiency. When new bags are placed in a baghouse, they do not have the initial dust cake buildup to help filter the airflow. A bag without a dust cake is susceptible to moisture which can result in a higher differential pressure. As mentioned previously a high differential pressure means a pulsing cycle is necessary resulting in energy consumption, and too much pulsing can decrease the bag life. The image below shows the results of a test conducted on bags with and without pre-coat powder.

Utilizing a leak detection kit

The longer a filter bag is used the more likely it is to get a tear in the bag. Manually inspecting the bags for rips or tears is one way to test for leaks, but this can be time consuming requiring a longer shut down period of the baghouse. Often times manually inspecting each bag can lead to overlooked leaks that may be too small to catch on the initial glance. Using a leak detection kit ensures accuracy and is the fastest way to check for any holes in the bags. The kit consists of two main components; the ultra violet leak detection powder and the blue LED test light. First apply the powder into the dirty air side of the dust collector. After application use the LED light to inspect the clean air plenum of the baghouse. The powder will have a bright glow under the test light around the bags where there are leaks. Leak detection powder can also detect torn seams, improper installation, cracked tube sheets, broken welds, and more.

Dust collectors are complex equipment that take time and effort to maintain. If you take the proper steps in taking care of the filter bags and optimizing the cleaning cycle, you can increase the life and efficiency of your pulse jet baghouse.