9 Elbows/Bends to know about for Pneumatic Conveying

In any pneumatic conveying system, no matter how well designed, a change in direction will be needed. The type of elbow to be used is an important decision when designing or upgrading a system. Listed below are 9 different types of elbows and their various application abilities.

Visit our webpage for elbows, bends, and other components for pneumatic conveying systems.

Spiral Grooved Elbows

Some plastic pellets cannot be conveyed by conventional smooth tubing due to stringers and angel hair. The angel hair problem requires special treatment. Spiral-Grooved Elbows are specifically designed to be a highly effective solution. In essence, Spiral-Grooved Elbows prevent angel hair residue from being collected. Internal spiral-grooved bends increase turbulence of materials passing through the system to reduce clogging due to angel hair or stringers.

Shot-Peening Elbows – Non Directional

Shot peening is a cold working, non-directional process in which the surface of a part is bombarded with small spherical media called “shots.” Each piece of shot striking the material acts as a tiny peening hammer, imparting a small indentation or dimple to the surface. The resulting dimple may serve to disrupt the boundary layer of the flow creating turbulence, thus allowing particulates to agglomerate along the wall of the pipe and/or tubing.

Shot-Peening – Directional Elbows

These elbows help reduce stringers and angel hair when conveying plastics. An “internal finish” is a directional roughness applied by a proprietary shot peening process. This finish is consistent, and covers 100% of the internal surface of the pipe. The impact of the round shot compresses the surface to produce a form of cratered roughness. The resulting dimple serves to disrupt the boundary layer of the flow creating turbulence, and the tendency of particulates to “tumble” rather than slide along the wall of the pipe or tubing.

Ceramic Back Elbows

The Ceramic Back elbow has a jacket across the back of the core elbow which is approximately ½” of ceramic compound. This compound has a Mohs hardness of 9+, second only to diamond, which has a Mohs hardness of 10. The ceramic jacket and core elbow is then wrapped with an exterior material to maintain hoop strength. Once the core elbow has worn through, the abrasion is then transferred to the ceramic outer jacket. The metal core also acts as a static conductor.

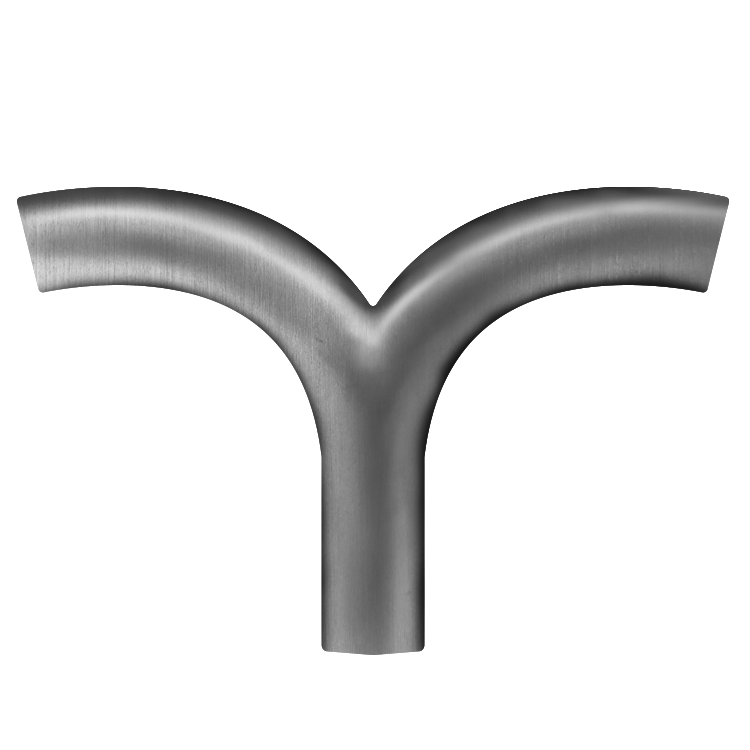

Bifurcated Elbows

Bifurcated elbows, or bends (also known as coped wyes) can be fabricated from any bent elbow in tube or pipe sizes, and are available in double and triple bifurcations. They are available in carbon steel, galvanized steel, stainless steel and aluminum. Bifurcated bends operate efficiently on rail-car vacuum unloading manifold systems.

Hammertek Smart Elbow

The Hammertek Smart Elbow provides long-wearing protection from elbow failure in pneumatic and hydraulic conveying systems. Combining superior design with a selection of alloys, the Hammertek Smart Elbow can withstand virtually any conveying situation, especially when high technology coatings are used. Corrosives and abrasives can be conveyed safely, will no longer cause leaks, costly downtime, or the disposal problems which worn elbows inevitably create.

Induction Hardened Elbows

Specialized heat induction hardening raises the material's Brinell hardness, making it highly abrasion resistant.

Porcelain Enamel Lined Elbows

Porcelain lined elbows are a cost-effective solution when moderate abrasion is encountered. Powder coating the interior, and then heating to over 1,500 degrees creates the porcelain enamel lining, a glass-like smooth finish on the inside diameter of an elbow. The standard lining is 8 to 10 mils, thick or is available with a heavier coating of 12 to 15 mils thickness.

IAC carries a wide range of elbows for pneumatic conveying – from standard light gauge tube bends, to extra heavy duty abrasion resistant elbows. Special shapes, offsets and non-standard radius bends are also available. IAC can provide the correct type to fit any application.