How to Solve Material Build-up and Flow Problems in Dry Bulk Storage Bins

Reliable material handling is vital in process related industries to achieve efficiency optimization, material uniformity, and debottlenecking. These goals can be upset by poor solids flow. Resins, pellets, grains, powders, wood dust and many other fine materials are all susceptible to poor flow. Flow problems can occur throughout the plant and seem to always be found in bulk storage silos, hoppers, and conveying lines.

We see it across all industries, dented up hoppers and duct work with a 12LB sledge hammer not too far away. This practice provides limited results in exchange for thousands of dollars’ worth of damage. In some cases the equipment can be damaged beyond repair.

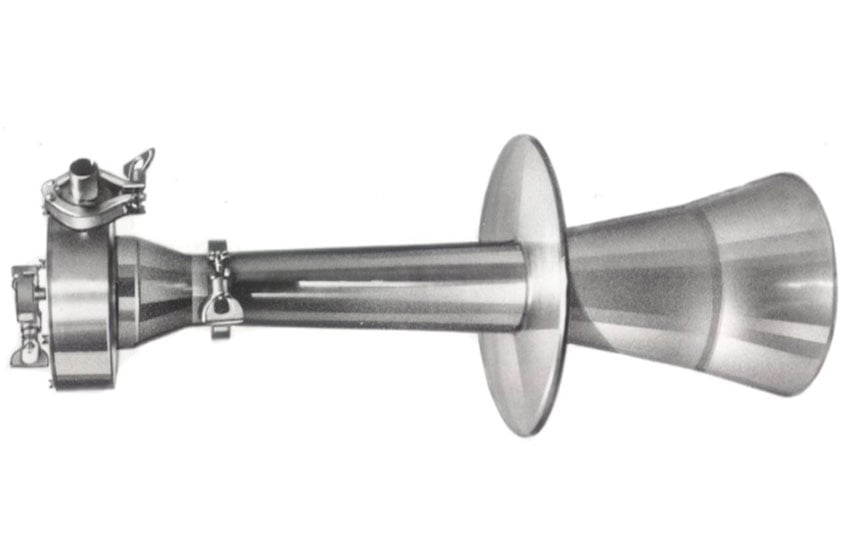

There are a few unique products available today that are used to enhance material flow; Acoustic Cleaners, Air Pads, Flow Cones, and Vibrators. Each of these products produce focused energy that will fluidize the material eliminating Arching, Bridging, Ratholing, and Sidewall Buildup. The cleaner used, how it is sized, and where it is mounted will be dependent on the type of buildup you are experiencing.

Arching and Ratholing can be eliminated by a properly sizing and mounting an acoustic cleaner. The sound energy produced is directed to the problem area. The high energy / low frequency sound-waves will cause the material to resonate, allowing the material to fall and flow freely. Sidewall Buildup can be solved with hopper mounted vibrators 180 degrees apart. Bridging is cured by installing Flow Cones in the hopper, aerating the material allowing it to flow easily. Installing these products properly can spare the vessel from the damage caused by sledge hammers.