IAC Tip of the Month Video: Inspection of Doors in Ductwork

Inspection doors are important for maintenance on long runs of horizonal ductwork, but there is one door design that can cause issues with your ventilation system’s airflow, reducing your capacity to meet production rates. It also, allows for material to build up, which in the worst and most expensive cases seen by Luis, causes ductwork to collapse, sometimes bringing down a section of a building.

Learn what style of inspection door is best for use on readily available ductwork, and why retrofitting existing ductwork with ‘bad’ inspection doors should be on your next maintenance outage project list.

In this tip-of-the-month video, IAC process engineer Luis Castano discusses inspection doors in ductwork.

Video Transcript: Why do we need to talk about this? Generally, you wouldn’t need to talk about inspection doors in ductwork if the ductwork was designed per Global recommendations.

One recommendation is that we don’t want to run horizontal ductwork for long lengths. Why? Because even if we apply the adequate velocities, we’re going to have some drop out, and that dropout can build up to become a problem.

Then there's many installations where we cannot have up-and-down design of ductwork to avoid horizontal sections. It can not be done because of space requirements, or building design, so there are many cases where we do need to run horizontal ductwork.

To do this we strongly recommend putting inspection doors to avoid material accumulation because there's been some cases where the ductwork collapses, sometimes bringing part of the building down. It's not only an environmental and personnel safety hazard, but it's an expensive problem.

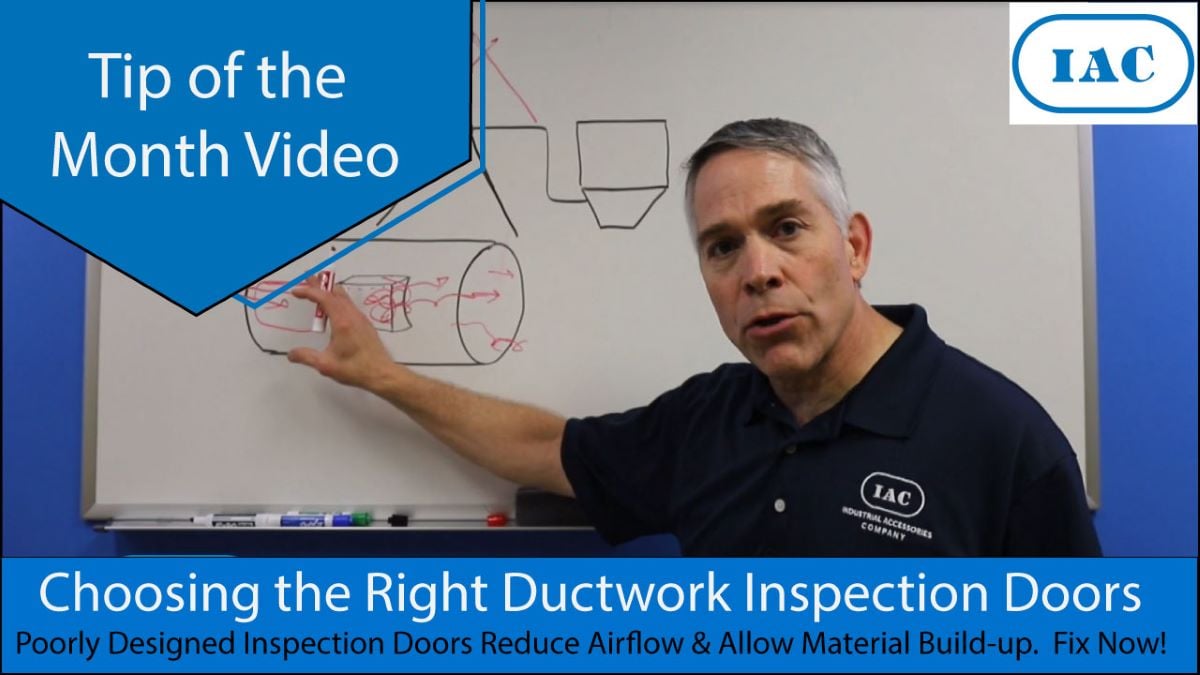

What I have drawn here is horizontal ductwork going to different places to vent in the plant, and a typical inspection door that is a rectangular protrusion from the round ductwork.

Now think about it: air flows moving on a high velocity here around 4,000 feet per minute and then we have this notch protruding out of a round ductwork that obviously creates turbulence, which then continues to disrupt the airflow down the duct.

What's the big deal? Material accumulation, but more than anything, slowing down and reducing the suction and the velocity which causing the problem of material accumulation.

See an example of how IAC helped one of our customers solve ducting issues that were causing down time and lost production: IAC Solves Ducting and Dust Collection Issues at an Industrial Sand Plant.

What we recommend when you have horizontal ductwork is to install inspection doors that mold to the shape of the ductwork so that the airflow moving inside is not disrupted. This type of inspection door is readily available off the shelf. We also recommend periodic inspection of horizontal ductwork to see if material is accumulating, and if it is, determine a solution to stop the accumulation.

In conclusion, avoid installing inspection doors that create a pocket where turbulence is introduced to your air flow as it is very bad for your ventilation system. If you want to discuss this in more detail, please contact us and we can recommend a solution. Thank you!