Is It Possible To 3D Print A Power Plant?

There’s no doubt that 3D printing is one of the most intriguing technologies today. Starting in the 1980’s, 3D printing has really taken off over the last decade. Within the past few years the technology has proven to be more versatile than anyone could have imagined. In 2018 alone there were car components, bridges and even houses that were 3D printed!

The technology behind 3D printing is known as Additive Manufacture. Additive Manufacturing is the process in which 3D objects are built by layers. A digital file, for example a CAD sketch, is created for the 3D printer to read and print out the layered 3D object. The benefits of this layered technology are speed and cost; because materials are not wasted, and the printer doesn’t stop printing until the object is complete.

Evidence of 3D printed Structures

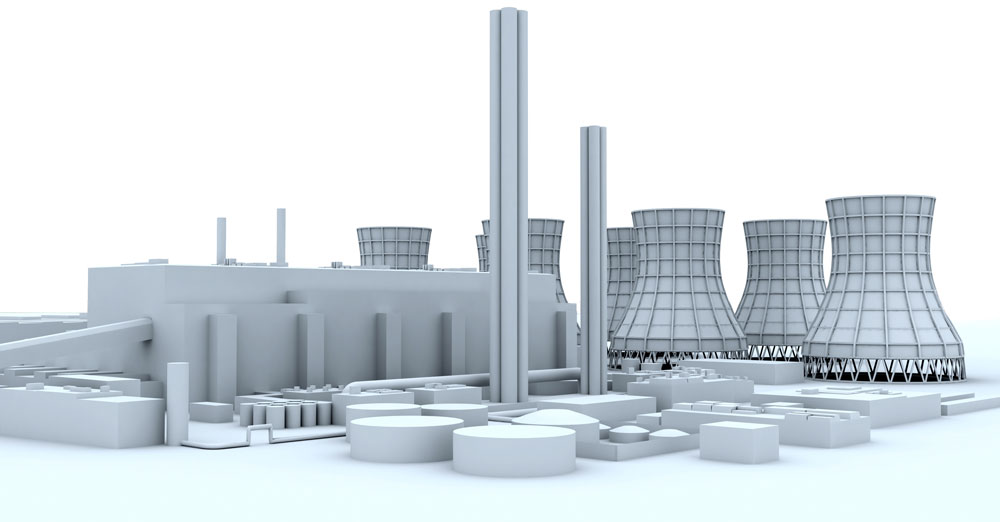

For years rapid prototyping technologies have been used to produce small scale models of structures like buildings and factories. In theory, the same techniques used in printing a model of a plant could be used at a larger scale and with different materials.

Evidence of this larger scale printing being attainable can be seen by this example of a 3D printed house. These 3D printed houses are being printed up to 800 square feet at a fraction of the cost that traditional built houses go for.

Another amazing example of a 3D printed house can be found in Nantes, France where a family of five currently resides in. At 20% of the cost of a traditional home, this 3D printed home spans 1,022 square feet and was built in just 54 hours! The home is insulated, fully functional and includes a temperature control system.

If the 3D printed houses aren’t enough to convince you that an entire plant could be 3D printed, look at what NASA thinks about the future of 3D printing. One of the Centennial Challenges hosted by NASA is a competition to 3D print livable habitats for deep space exploration. The purpose behind the challenge is to advance the construction technology required for sustainable housing solutions for Earth and beyond.

Does the printer exist?

If it is possible to 3D print houses, and structures for NASA, in theory it seems possible to print a power plant. However, 3D printing houses is one thing but does the printer exist that could create an entire plant?

Let’s look at a couple of printers that could potentially build a plant.

TU/e Concrete Printer

As described in the name, this 3D printer can print large scale structures using concrete. The printing method involves a large robotic arm that layers the wet concrete inside the confines of its enclosure. Structures can be printed on-site or in a factory and then transported to the build site. Plants often incorporate very tall structures like stacks and silos, which could range anywhere from 30 to 300 feet high. Due to its limitations of only being able to print 36 feet long, 16 feet wide and 13 feet high, the TU/e Concrete Printer would need to print the plant in pieces which would later need to be assembled. Assembling the printed pieces would not be an efficient way to 3D print a plant.

MIT 3D Printer for Construction

Researchers at MIT have developed this 3D printer with the capabilities of creating the basic structure of an entire building. The printer features a mobile unit that carries a robotic arm attached to a crane. Its unique features enable MIT’s printer to create building designs that are not possible with traditional building methods, and it is not limited to building objects within an enclosure.

This article posted in MIT News describes some of the benefits of their printer.

“The system consists of a tracked vehicle that carries a large, industrial robotic arm, which has a smaller, precision-motion robotic arm at its end. This highly controllable arm can then be used to direct any conventional (or unconventional) construction nozzle, such as those used for pouring concrete or spraying insulation material, as well as additional digital fabrication end effectors, such as a milling head.”

One of the benefits of MIT’s printer is there are no size limitations to what it can create; a necessity when it comes to printing an industrial plant.

“This free-moving system can construct an object of any size. As a proof of concept, the researchers used a prototype to build the basic structure of the walls of a 50-foot-diameter, 12-foot-high dome — a project that was completed in less than 14 hours of “printing” time.”

Combining automation and mobility means that challenges with locations could be a thing of the past.

“The ultimate vision is in the future, to have something totally autonomous, that you could send to the moon or Mars or Antarctica, and it would just go out and make these buildings for years.”

Utilizing MIT’s crane and mobile system of their 3D printer appears to be a step in the right direction to 3D printing something as large and complex as a power plant.

Not everything can be 3D printed

There is so much that goes into taking a power plant from the initial drawings to the finished project that it would be unrealistic to 3D print all the complexities. From the ground wiring to the in-plant electrical work, there is still a need for manual labor even when it comes to 3D printing a plant. There are also material limitations with 3D printers, like glass for example, which would require manual installation on-site.

The final verdict

Regardless of the current limitations it is still feasible to 3D print the structure of a plant. As we’ve seen from previous examples, 3D printing can offer a savings in costs, materials and time. The future of industrial plant construction could be one that is automated, faster and cheaper. Only time will tell if 3D printing a plant will become a reality.

IAC continues to monitor emerging technologies through our commitment to innovation. While 3D printing remains prohibitive in most cases through the limitations discussed above, IAC will explore and employ this technology where it creates value for the customer in terms of efficiency or plant performance.

At IAC we don’t just build plants, we bring ideas to life. Visit our about us page to learn more about the industries we serve.