Overlooked Aspects of Combustible Dust Design & NFPA Requirements

Combustible Dust - How Concerned Should You Be?

Did you know that combustible dust is a leading cause of industrial fires and explosions, costing businesses billions annually? These fine particles, accumulating on surfaces and in the air, pose severe risks to operations and safety. Beyond threatening lives and infrastructure, dust infiltration can clog machinery, accelerate wear, and drive-up maintenance costs. Frequent downtime for cleaning and repairs further disrupts production and impacts profitability. To safeguard employees and ensure operational continuity, businesses must prioritize effective dust management, routine maintenance, and strict adherence to NFPA standards.

- Read the full article: Combustible Dust: How Concerned Should You Be?

What is the NFPA?

The National Fire Protection Association (NFPA) is the leading organization for dust management and safety. Its standards are vital for protecting industrial workers and their environments. To address combustible dust hazards, the NFPA has established a series of requirements to minimize risks. Among these, the NFPA recommends maintaining dust concentrations below the Minimum Explosible Concentration (MEC) — the threshold at which dust suspended in air can ignite and explode. Furthermore, NFPA mandates that combustible dust should not accumulate in work areas or HVAC systems. Regular maintenance, including filter replacement and post-production clean-up, is essential.

Transition to NFPA 660: A Unified Standard

The NFPA has consolidated six combustible dust standards into a single, comprehensive standard: NFPA 660. This new standard, titled 'Standard for Combustible Dusts and Particulate Solids,' was officially released in 2024 and supersedes the previous standards NFPA 61, 484, 652, 654, 655, and 664. This unified approach aims to streamline compliance, provide consistent guidelines, and enhance workplace safety. Facilities must take proactive steps to understand and implement the updated requirements, including reviewing their current Dust Hazard Analyses (DHAs) and updating safety practices.

Key Updates Under NFPA 660

While NFPA 660 retains many of the principles from previous standards, it introduces new expectations:

- Enhanced DHA Procedures: Facilities must conduct thorough DHAs to identify all potential sources of combustible dust and assess the consequences of an explosion.

- Stricter Housekeeping Requirements: More rigorous guidelines to monitor and limit dust accumulation in production areas and systems.

- Risk Assessment Methodologies: Greater emphasis on standardized risk assessments to ensure consistent evaluations across industries.

Facilities should act now to evaluate how these changes may affect their operations and ensure they are prepared for compliance.

IAC's Dust Hazard Analysis Services

At IAC, we specialize in helping facilities identify and mitigate combustible dust hazards. Our Dust Hazard Analysis (DHA) service includes a comprehensive facility walk-through by a combustible dust specialist, who provides a detailed report of findings and actionable recommendations. This report empowers facilities to implement necessary changes in ways that fit their specific needs and budgets. As always, our goal is to deliver unbiased, practical solutions that prioritize your safety and compliance.

Partner with IAC for Your DHA Needs

Combustible dust hazards are not just a regulatory challenge—they're a matter of workplace safety. With NFPA 660 introducing unified standards, there’s no better time to act. Let IAC help you navigate these changes with our expert Dust Hazard Analysis services and tailored solutions.

Contact us today to learn how we can support your journey to a safer and more compliant operation.

Preparing for NFPA Compliance

Our DHA services are designed to help you stay ahead of regulatory changes. With NFPA 660 introducing new standards, now is the time to ensure your facility is prepared. Let IAC assist you in:

- Conducting a DHA that aligns with NFPA 660 requirements.

- Implementing effective dust prevention and management practices.

- Upgrading dust collection and containment systems to meet stricter standards.

- Evaluation for additional new equipment.

Example of How IAC Helped a Customer with the DHA & How it Improved their Operation and Employee Health

Many of IAC’s customers work with dangerous and hazardous materials. When creating solutions for handling harmful materials, IAC works quickly to help these organizations create safer processes for their employees and production. IAC did this recently by taking a few fast measurements and rapidly creating a custom component to eliminate the spread of a harmful powder in an ingredient facility, which took numbers from three and a half times the exposure limitation to less than 10% of the threshold.

- Read the full article: IAC Baghouse Installation Eliminates Harmful Powder Exposure

IAC's Solutions for Combustible Dust Management:

In addition to DHA services, IAC offers a wide range of products and systems to help facilities manage combustible dust effectively:

- IAC Baghouse & Dust Collector Designed for Explosive Applications

- IAC Pneumatic Conveying Systems

- IAC Smart Plant Remote Monitoring Systems

- IAC EPC Capabilities

Reach out to IAC today and put our experience to work for you! We can help you meet production rates, keep production costs down, and ensure a safe working environment for your staff.

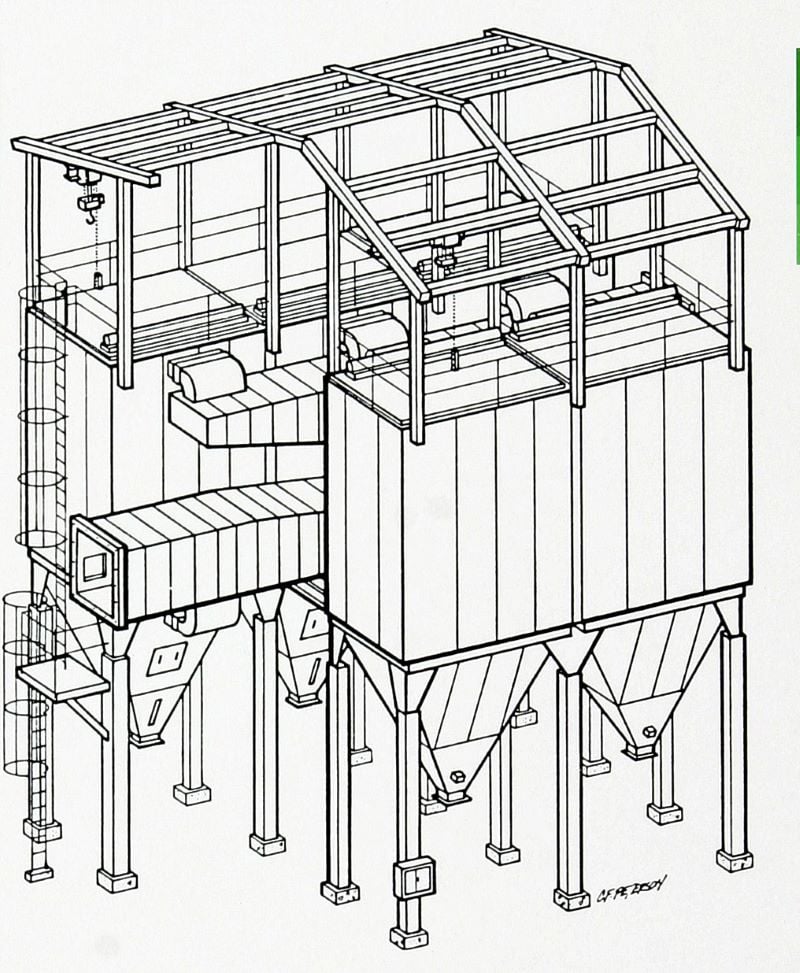

IAC Fluid Bed Combustion Baghouse Drawing