OSHA Final Rule on Silica and How it Affects You – Video

On March 24 OSHA announced a final rule to improve protections for workers exposed to respirable silica dust. If your company has personnel at risk for...

Posts by:

On March 24 OSHA announced a final rule to improve protections for workers exposed to respirable silica dust. If your company has personnel at risk for...

OSHA announced a final rule on March 24 to improve protections for workers exposed to respirable silica dust. According to the agency, the silica rule will curb...

Proper Filter Bag installation is the single most important component of a leak free, efficient dust collection system. There are many different types of...

Manufacturing facilities are producing more today than ever before. They have added equipment, sped up processes, and increased throughput. Plants can’t afford to...

The service life of filter bag media in an industrial baghouse can vary widely depending on several factors, including the type of contaminants being filtered, the operating conditions of the baghouse, the design and quality of the filter bags, and the maintenance practices employed.

In general, filter bags in a baghouse are designed to be replaced periodically due to wear and tear from the filtration process. The average service life can range from six months to several years. Some key factors influencing the lifespan of filter bag media include:

Reliable material handling is vital in process related industries to achieve efficiency optimization, material uniformity, and debottlenecking. These goals can be...

If you’re thinking about replacing your pulse jet baghouse due to failing performance but don’t have the funds to do so, read on. Many times you don’t need to replace a low performing pulse jet baghouse, as there are some cost effective steps that can be taken to keep the baghouse running efficiently.

One of the core operations of IAC business is providing routine maintenance and inspection programs with the plants we work with. After many years of conducting inspections, repairs and start-ups we’ve noticed trends where the plants we work with are unaware of aspects involving maintenance. One particular issue that consistently arises involves pre-baghouse start-up inspections. Not only do we want to help our customers maintain their equipment, we want to educate them as well to avoid future issues.

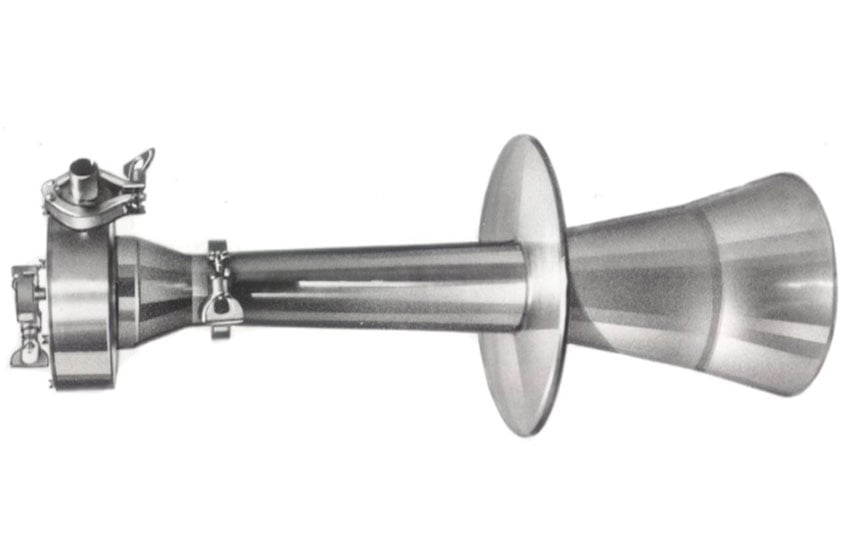

Sonic Horns (also called acoustic horns) produce high intensity, low frequency sound vibrations that fluidize and remove unwanted particulate build-up or bridging.

The purpose of an industrial fan is to provide a large flow of air or gas to various processes. This is usually directed through a rotation of blades which are connected to a hub/shaft, and driven by a motor.