Questions About Airflow for Round Dust Collectors

Recently the following questions came in for our Blue Crew Field Service Teams:

“For round collectors, what are the provisions to control the gas to individual dust...

Posts by:

Recently the following questions came in for our Blue Crew Field Service Teams:

“For round collectors, what are the provisions to control the gas to individual dust...

How does moisture get inside a baghouse? There are five common ways as explained by Joe Haney, IAC Product Specialist. In this Tip-of-the-Month video series, we’ll take a look at the five most common ways moisture enters a baghouse, and offer solutions you can implement to prevent this problem and keep your baghouse dust collector operating at peak efficiency.

A common issue when it comes to baghouse design is that the baghouse is designed too small for what it’s intended for. If a baghouse is undersized this...

Inlet temperature leading into the baghouse plays a crucial role in any baghouse system. Your baghouse might have bags that are capable of handling...

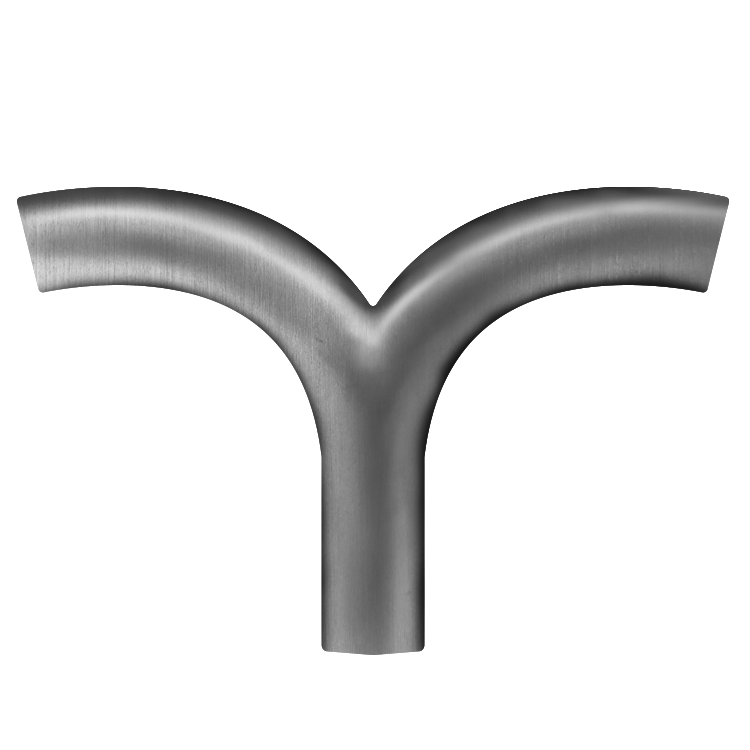

In any pneumatic conveying system, no matter how well designed, a change in direction will be needed. The type of elbow to be used is an important decision when...

Following proper start up and shut down procedures for your baghouse dust collectors is not only beneficial to the life of filter media in dust collector applications

The fit between the bag and the cage is critical for filters to perform properly. Filters that are too lose or too tight will...

IAC acknowledges industries’ concerns when it comes to maintenance issues and provides knowledgeable, innovative solutions to your problem.

A recent question came up for Dr. Vent Goode from a customer regarding Gravimetric/Volumetric.

Dr. Vent Goode,

I would appreciate your help on answering these...

Are you considering upgrading your old shaker or reverse air baghouse to a modern pulse jet style baghouse but are limited by budget, time, or square footage? If yes, then a baghouse conversion or rebuild might be right for your capital improvement project.

Outdated baghouse dust collectors, such as older shaker style or reverse air style collectors, can often be rebuilt or upgraded at a fraction of the cost of installing a new baghouse. Side walls, hoppers, and ductwork are reused in the conversion, and a new clean air plenum with bags and cages is supplied.