IAC and The Price Companies (TPC) Collaborate to Advance Biomass as a Clean Renewable Energy Solution

Posts by:

In this month’s IAC Tip of the Month, Nathan Petrie dives into a crucial yet often overlooked part of pneumatic conveying and dust collection systems: pipe supports. Whether you’re designing a new system or troubleshooting an existing one, understanding static vs. dynamic loading and planning for maintenance accessibility can save time, money, and future headaches.

OVERLAND PARK, KS – Industrial Accessories Company (IAC) has been named to design, build, and commission two waste heat biomass drying systems for SDI Biocarbon Solutions, LLC.

Hi, Joe here from IAC. As we gear up for the National Lime Association (NLA) Meeting this June, there are several critical developments in the lime industry that we’re focusing on. Here are five key points we want to highlight:

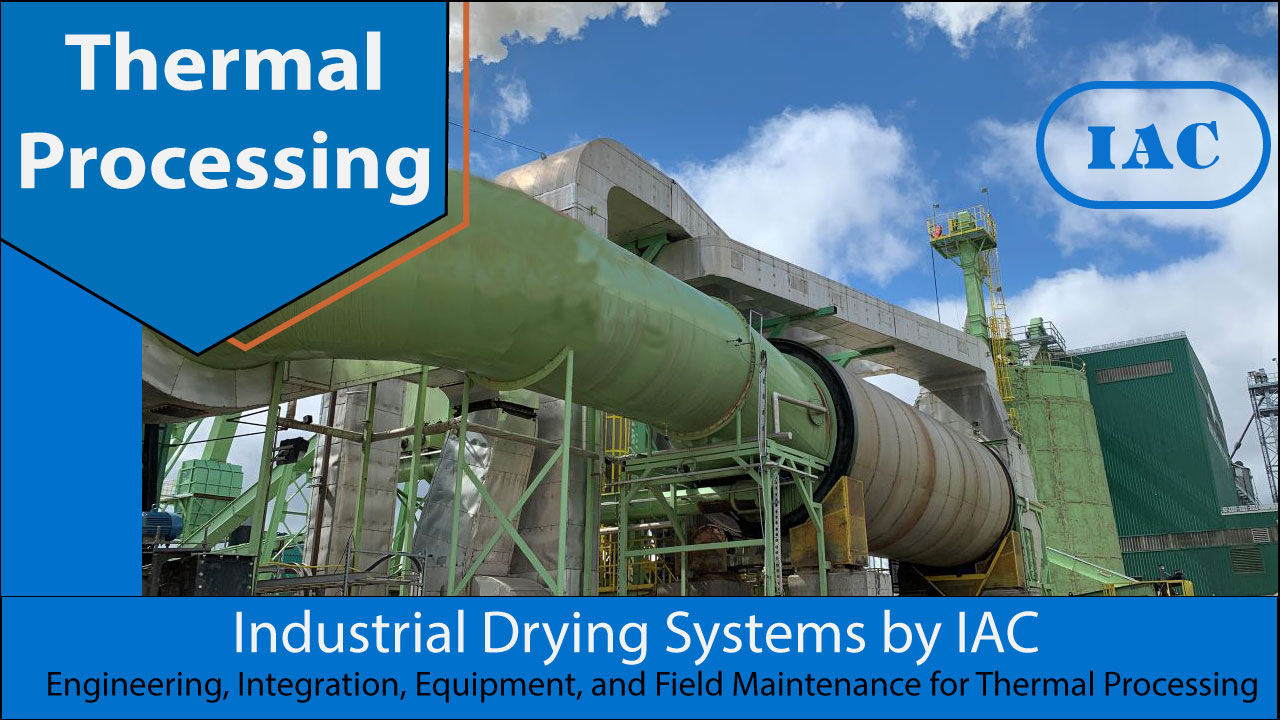

IAC offers complete thermal processing solutions for biomass processing, and biomass energy production. We design and fabricate rotary dryers, calciners, dust collection baghouses, cyclones, pollution control equipment, dry bulk storage systems, transload systems, mechanical and pneumatic conveying systems. In addition to our OEM equipment and engineered systems expertise, we are a full service industrial EPC contracting company.

When discussing pneumatic conveying systems, handling the "ends of the line," both the feed end (where material enters the system) and the discharge end (where material exits the system), is essential for efficiency, reliability, and maintaining product quality. Here’s a comprehensive guide on how to approach both ends, focusing on the initial feeding of material into the line and the effective removal of solids from the conveying gas at the discharge end.

What is static pressure in a dust collector system? In terms of airflow, static pressure is a measure of the resistance that air encounters while moving through the ventilation system before and after the dust collector, which could be a baghouse, filter receiver, cyclone, or bin vent.

The use of sound vibrations produced by sonic horns, as a means of fluidizing unwanted dust and agglomerated particulate in industrial process equipment, has been a well accepted practice for years. Sonic horns have been used to clean filter bags in baghouses in the carbon black and cement industries since the 1950s. These early sonic horns proved that acoustic energy could improve filter bag cleaning in conjunction with the primary reverse-air cleaning however their benefit was not fully realized throughout the industry as they are today.

Sonic horns began their present popularity in the 1980’s after the utility industry started using sonic horns to help reduce baghouse pressure drop, which was limiting plant generating capacity. Sonic horns became extremely cost effective in improving bag cleaning, thus increasing the power plants megawatt generating capacity.

Introducing IAC's Quick Ship Program for popular sizes and styles of industrial dust collectors! We know our customers thrive on maximizing uptime in their production facilities, so we created a quick ship program which cuts industry standard lead times in half!

Today we’re talking about IoT devices - specifically wireless devices. This is a request that seems to be increasing a lot from our customers. You have a lot of measurables at your plant, signals, digital and analog that you can make a difference in how well your plant is working. There are new, low cost ways to measure this kind of information, and it's with wireless IoT enabled devices.