IAC Articles, Events, and News

Posts by:

IAC

-1.jpg)

Visit IAC’s Booth & Presentation at the 2022 IEEE Cement Conference

After being held virtually last year, the IEEE-IAS/PCA Cement Conference is back in person this May 1-5th at the MGM Grand in Las Vegas, NV. 2022 marks the 64th anniversary of this annual conference, and IAC’s 17th year of attending and exhibiting. As a Gold Sponsor, IAC supports the goals of the event to facilitate discussion regarding new developments and information on a variety of subjects including decarbonization, company goals, and new technology.

IAC Live Chat Feature Eliminates Wait For a Callback

Quick Maintenance Benefits Bottom Line for Frac Sand Plant

IAC’s Permian Basin Service Team isn’t afraid of hard work or long hours. Twelve members of the service team recently completed a 2,800 filter bag changeout,...

Portable Industrial Vacuum Systems for Frac Sand

IAC strives to provide practical solutions for plant management. With the IAC600T Series of portable industrial vacuums, facilities are able to schedule downtime on...

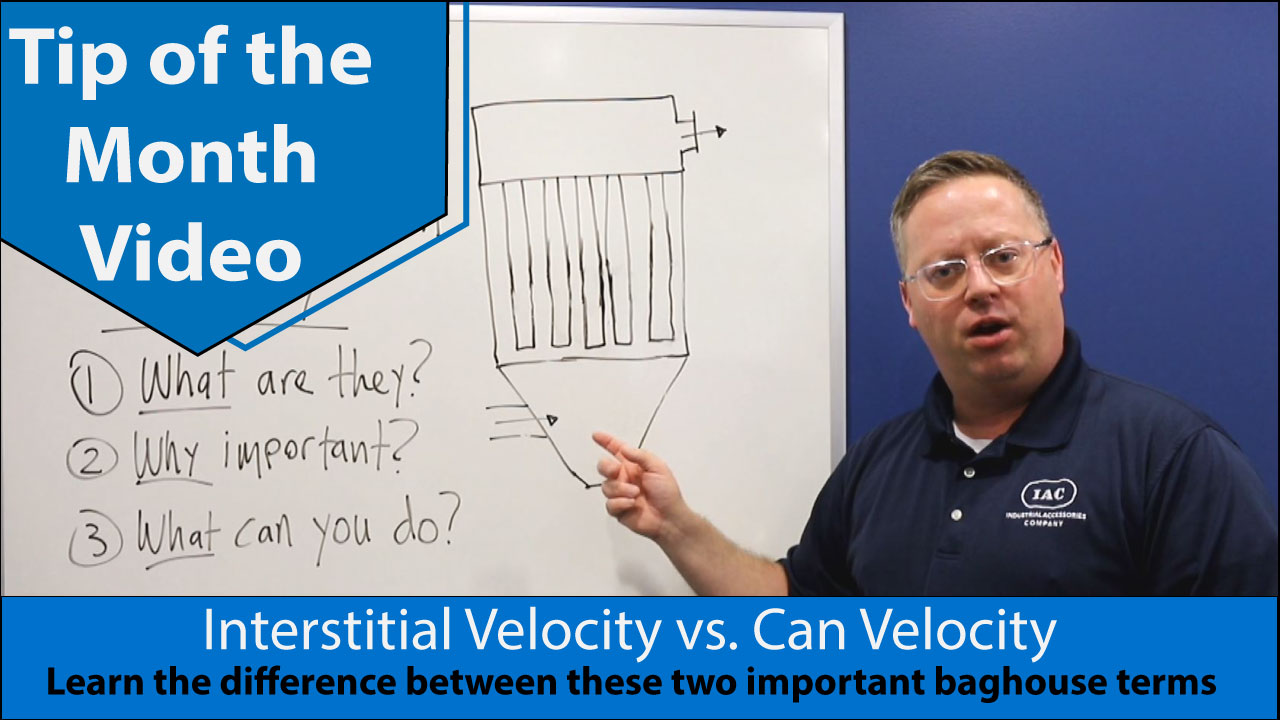

How Can Velocity and Interstitial Velocity Differ in a Baghouse Filter

Can velocity and interstitial velocity are commonly confused when proper filter selection and baghouse sizing are being decided because they are very similar when filter bags extend to the hopper level. Can velocity is the vertical gas velocity throughout the housing, above the hopper level but before reaching the bottom of the bags. Interstitial velocity is the vertical gas velocity once the flow is at the bottom of the filter bags.

Powder & Bulk Solids Webinar: Hood Design for Effective Dust Control

IAC is excited to co-sponsor the PBS Dust Collection Webinar, "Hood Design for Effective Dust Control", being presented on Tuesday, January 25th, 2022.

The IAC Filter Newsletter – December 2021

Read IAC’s latest news in the Filter Newsletter. Featured stories include a supply chain update, sales success, machine guarding, upcoming tradeshows, and winterization.

Custom Machine Guards Keep Your Employees Safe

The Occupational Safety and Health Administration (OSHA) released their Top 10 Most Cited Violations for 2021. Coming in at number ten on the list is a repeat offender – Machine Guarding. The same violation is also a common recurrence on the Mine Safety and Health Administration (MSHA) Top 20 Violations each year. This easily rectified violation accounts for approximately 2,000 citations a year. IAC can help your facility avoid this issue quickly and easily to save you money and keep your employees safe.

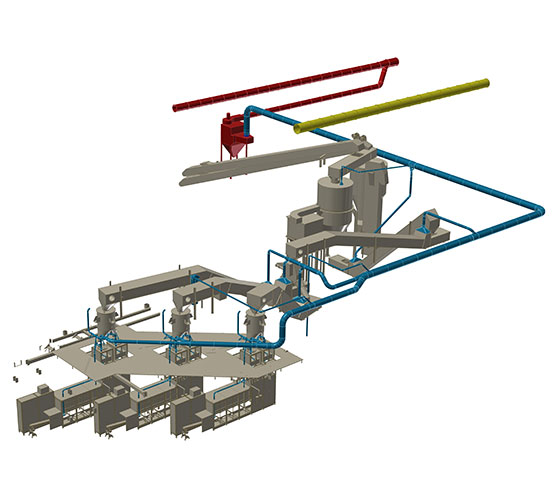

Smart Buying Decisions for Pneumatic Conveying Systems

From the smallest elbow to the largest bin vent, knowing each part and piece of equipment is created for your particular pneumatic conveying process will help you save money, plan for maintenance, limit employee exposure, save energy, and increase your production rate. Over time, repeat fixes can become costly. Thus, it is important to ensure your system is outfitted specifically for your application and material.