IAC Articles, Events, and News

Posts about:

Baghouses & Dust Collectors (5)

The Ultimate Guide to Baghouse Filter Bags

Do you ever question the reasoning behind why a filter bag has failed? Or have you never fully understood the importance of certain specifications related to your baghouse? Perhaps you’re not for sure about which baghouse filters work best for your industry.

If so, then keep reading.

3 Reasons to Use Pleated Filters in a Dust Collector

Manufacturing facilities are producing more today than ever before. They have added equipment, sped up processes, and increased throughput. Plants can’t afford to...

Cost Effective Ways to Improve Your Pulse Jet Baghouse

If you’re thinking about replacing your pulse jet baghouse due to failing performance but don’t have the funds to do so, read on. Many times you don’t need to replace a low performing pulse jet baghouse, as there are some cost effective steps that can be taken to keep the baghouse running efficiently.

What you didn’t know about baghouse start-up

One of the core operations of IAC business is providing routine maintenance and inspection programs with the plants we work with. After many years of conducting inspections, repairs and start-ups we’ve noticed trends where the plants we work with are unaware of aspects involving maintenance. One particular issue that consistently arises involves pre-baghouse start-up inspections. Not only do we want to help our customers maintain their equipment, we want to educate them as well to avoid future issues.

Questions About Airflow for Round Dust Collectors

Recently the following questions came in for our Blue Crew Field Service Teams:

“For round collectors, what are the provisions to control the gas to individual dust...

Common Ways Moisture Enters Baghouse Ventilation Systems

How does moisture get inside a baghouse? There are five common ways as explained by Joe Haney, IAC Product Specialist. In this Tip-of-the-Month video series, we’ll take a look at the five most common ways moisture enters a baghouse, and offer solutions you can implement to prevent this problem and keep your baghouse dust collector operating at peak efficiency.

5 Reasons Why Filter Bags Fail Prematurely

1. Design

A common issue when it comes to baghouse design is that the baghouse is designed too small for what it’s intended for. If a baghouse is undersized this...

3 Things to Consider When Choosing Filter Bags for a Baghouse

1. Temperature

Inlet temperature leading into the baghouse plays a crucial role in any baghouse system. Your baghouse might have bags that are capable of handling...

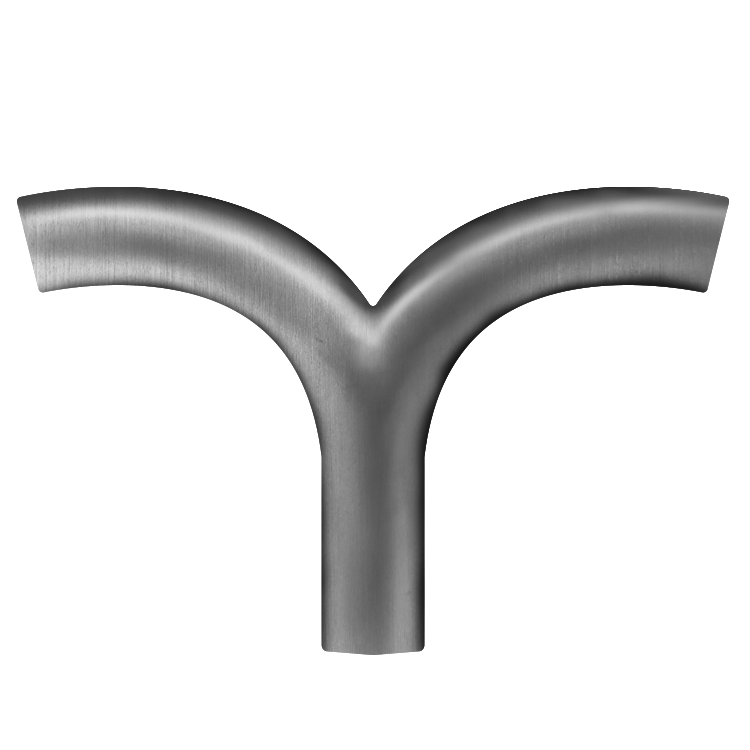

9 Elbows/Bends to know about for Pneumatic Conveying

In any pneumatic conveying system, no matter how well designed, a change in direction will be needed. The type of elbow to be used is an important decision when...