Powder & Bulk Solids Webinar: Hood Design for Effective Dust Control

IAC is excited to co-sponsor the PBS Dust Collection Webinar, "Hood Design for Effective Dust Control", being presented on Tuesday, January 25th, 2022.

Posts about:

IAC is excited to co-sponsor the PBS Dust Collection Webinar, "Hood Design for Effective Dust Control", being presented on Tuesday, January 25th, 2022.

IAC’s pulse jet baghouse winterizing kit protects your baghouse’s pulse valves and compressed air headers from snow, ice, and freezing weather - guarding against production interruptions and downtime.

Winter weather conditions can cause pulse valves to freeze open, or internal diaphragms to crack, bleeding the compressed air header of the air pressure and air volume required to effectively clean the bags.

Through growth of their business, a Midwestern USA handcrafter of custom cabinets and home fixtures needed to upgrade their woodworking dust collection system. After consideration of how their current dust collection system was handling the low moisture, mildly abrasive sawdust particulate, and their expectations for future growth, it was determined that the best course of action was to modify their baghouse dust collector and convert it to a high-pressure filter receiver.

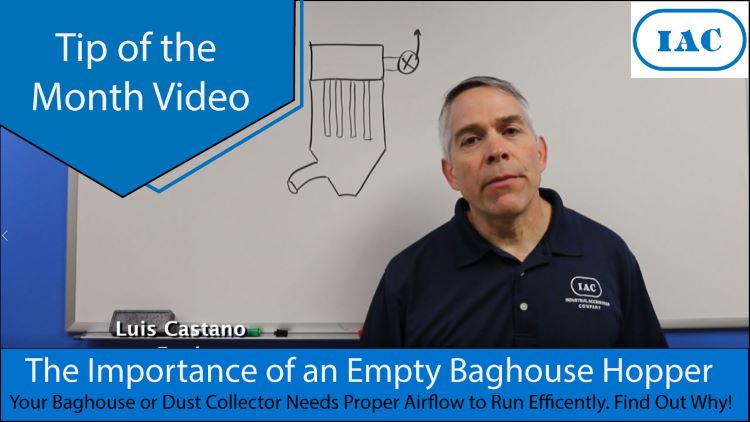

IAC Systems Engineer Luis Castano is back again with this month's Baghouse Maintenance Tip-of-the-Month Video about the importance of keeping your industrial baghouse or dust collector system's discharge hopper free of grain load (fallen materials).

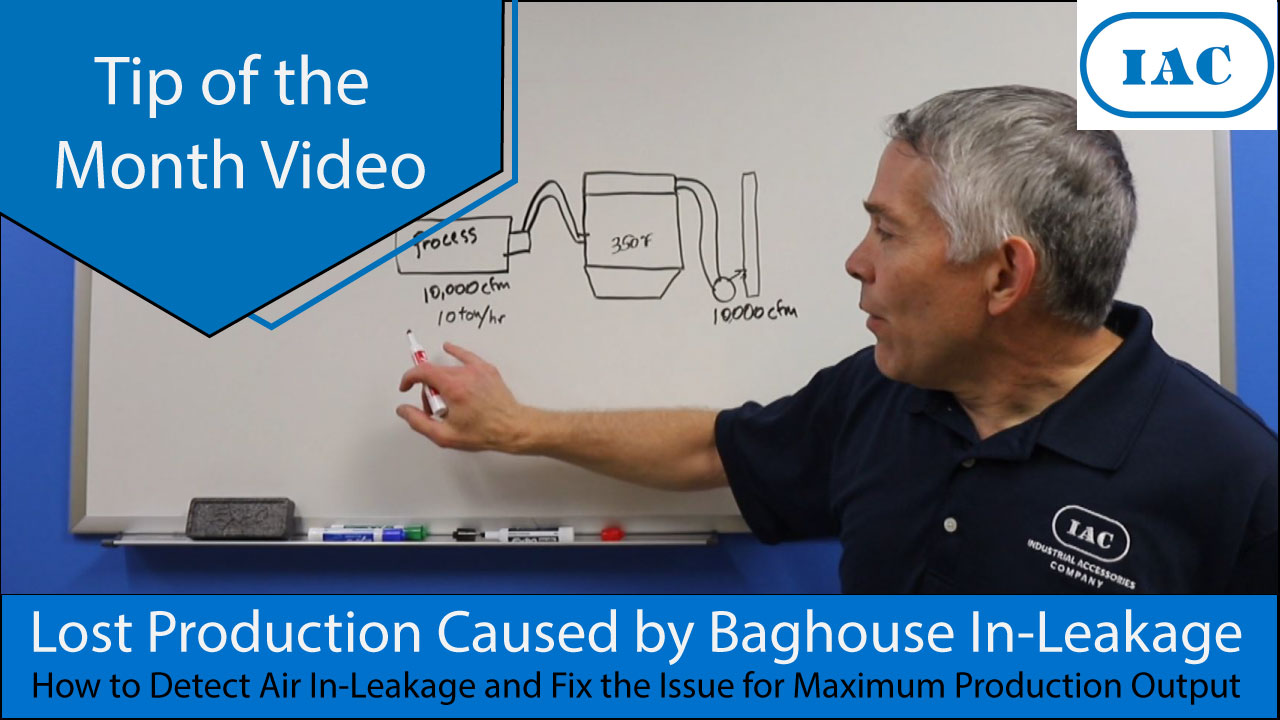

Do you hear a hissing sound coming from your baghouse’s housing, a discharge point, or expansion joint? That’s the sound of lost production, and lost profits. IAC Process Engineer Luis Castano has inspected hundreds of baghouse dust collection and vent systems; lost production capacity due to In-leakage is the problem he finds most often. In-leakage reduces the baghouse system’s ability to process airflow at rated CFM capacity, which in turn causes the process equipment’s production to drop. High temperature air magnifies this effect, slowing production system down even more.

Many of IAC’s customers work with dangerous and hazardous materials. When creating solutions for handling harmful materials, IAC works quickly to help these organizations create safer processes for their employees and production. IAC did this recently by taking a few fast measurements and rapidly creating a custom component to eliminate the spread of a harmful powder in an ingredient facility, which took numbers from three and a half times the exposure limitation to less than 10% of the threshold.

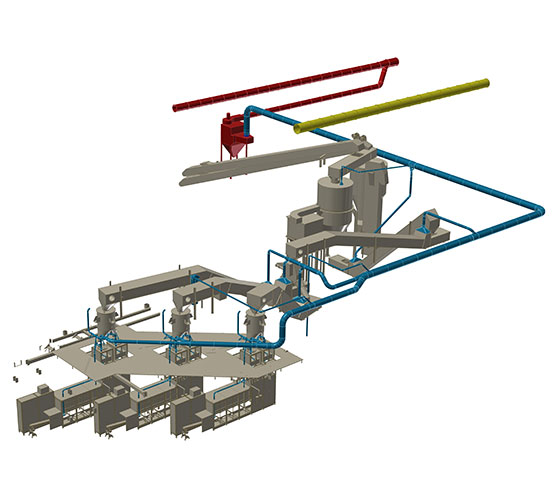

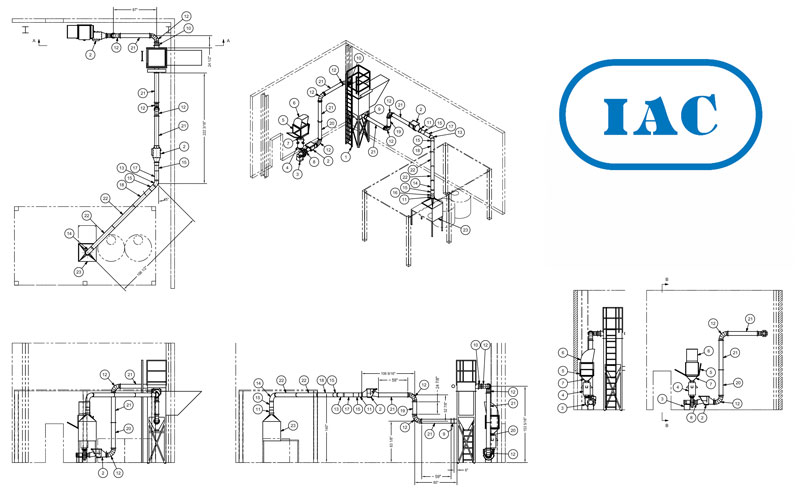

Naturally occurring pozzolans have been used in cement for thousands of years. In modern times, much of these natural materials were replaced with fly ash, which is a byproduct of burning coal for electric power generation. However, with more and more coal plants being shut down, the availability of fly ash is decreasing. This is creating a new demand for the old material, leading to the construction of new mining and processing facilities. With years of experience in mining and processing natural materials, such as frac sand, IAC is prepared to assist with the supply and installation of new natural pozzolan facilities.

In this month’s IAC Tip of the Month Video, Process Engineer Luis Castano offers an elegant and simple solution of how to modernize older reverse air and shaker style baghouses within the housing, and convert them to more reliable and easier to service pulse jet systems. Conversion can be done at a lower cost than replacing the baghouse, and will achieve required capacity, making the investment an excellent option for many operations.

Crane booms are in the air as the IAC and Adelphi Construction teams continue to make progress on the greenfield construction of the independent Reverse Air Baghouse Systems for two direct-current electric arc furnaces (DC-EAF), and two twin ladle furnaces (LF). IAC’s project managers keep the lines of communication open with our on site personnel, our OEM fabrication facilities and outside equipment suppliers, specialized transportation fleets, and our client to ensure the project continues to run smoothly.

Ever wondered how the Roman empire made such durable buildings? Like the Colosseum or Pantheon? They achieved those long-lasting architectural wonders by harnessing the power of natural Pozzolans!