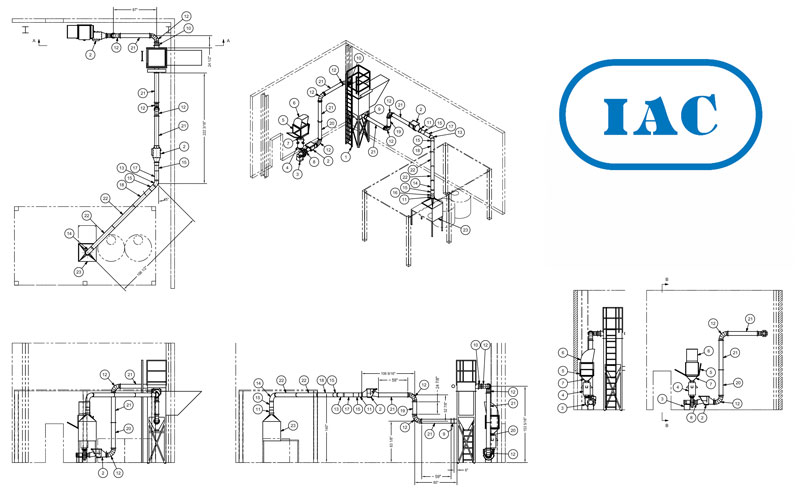

Baghouse to Filter Receiver Conversion for Woodworking Shop

Through growth of their business, a Midwestern USA handcrafter of custom cabinets and home fixtures needed to upgrade their woodworking dust collection system. After consideration of how their current dust collection system was handling the low moisture, mildly abrasive sawdust particulate, and their expectations for future growth, it was determined that the best course of action was to modify their baghouse dust collector and convert it to a high-pressure filter receiver.