Virtual Reliability Manager: How to Become a SMART Cement Plant

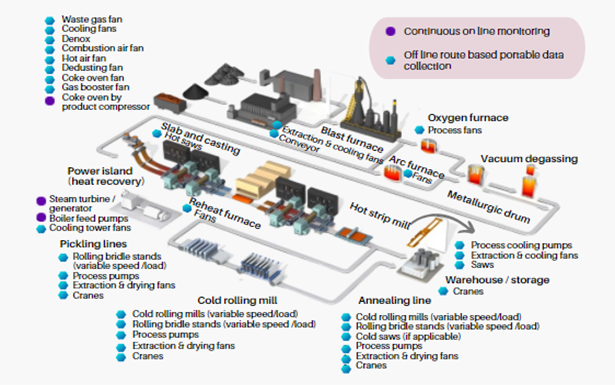

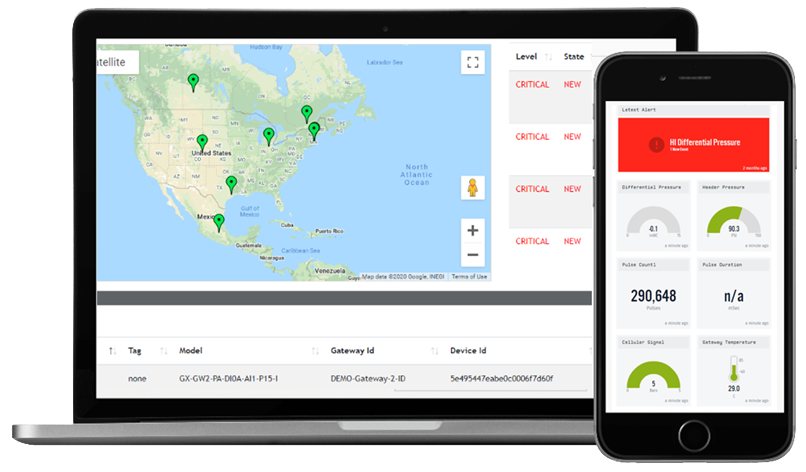

Cloud-based IoT control systems remotely monitor not only dust collector conditions, but universally monitor emissions, airflow, vibration, humidity, high temperature or any other data set, from anywhere on most any equipment around the globe. This increases the use of predictive maintenance.

Joe Haney, Product Manager for Fine Filtration and IAC's SMART Plant Remote Monitoring Technology, gave a presentation at the 2023 IEEE-IAS/PCA Cement Conference on the topic of utilizing IoT technology to connect cement plant processing systems to monitoring software which allows cement plant personnel to remotely monitor machine operations, thus saving valuable maintenance time and reducing the potential for unexpected down time.